- #1

Valentin1999

- 1

- 0

Hello.

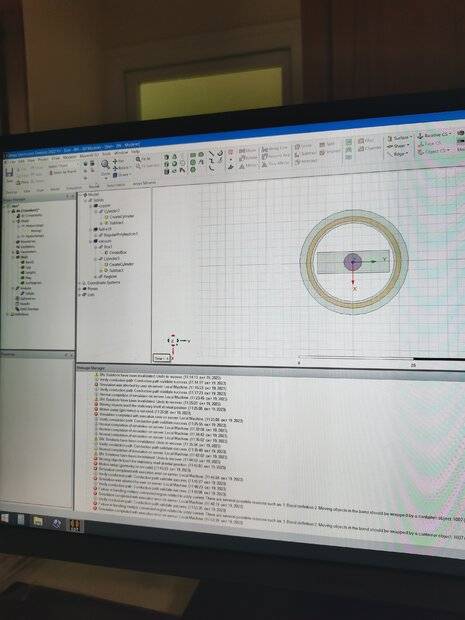

I have a magnetic core and a copper cylinder with a hole. I ask the cylinder to rotate and the magnet to move from left to right. I want to calculate Foucault currents in a copper cylinder, but an error appears.

"Failture in handing multiply connected region to eddy current. 1. Band definition. 2. Moving object in the band should be wrapped by a container object"

I Need a help.

I have a magnetic core and a copper cylinder with a hole. I ask the cylinder to rotate and the magnet to move from left to right. I want to calculate Foucault currents in a copper cylinder, but an error appears.

"Failture in handing multiply connected region to eddy current. 1. Band definition. 2. Moving object in the band should be wrapped by a container object"

I Need a help.