- #1

gears

- 1

- 0

Hi,

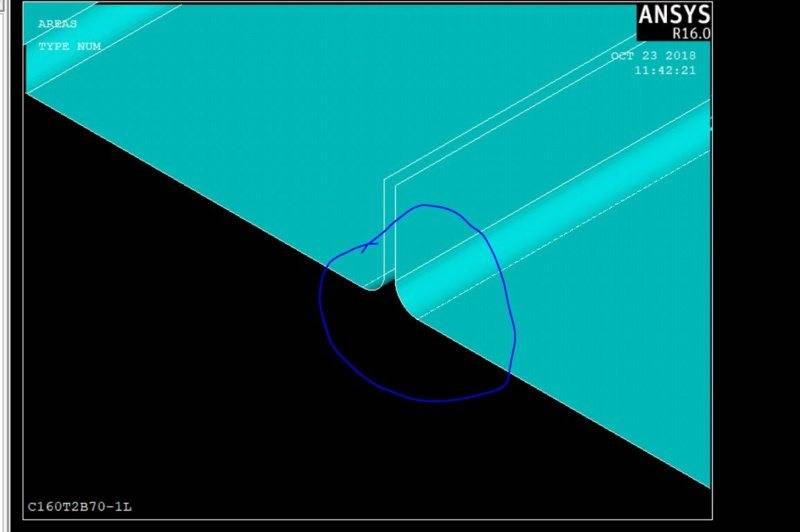

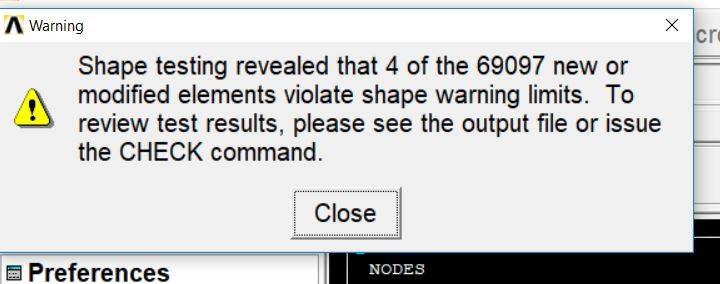

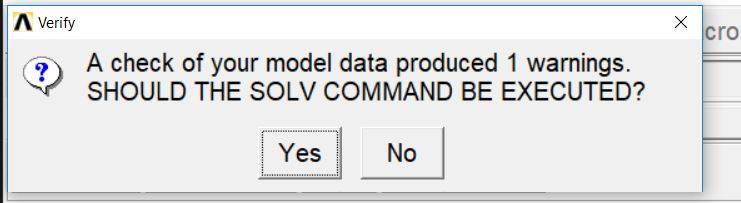

I am facing issues with my program. Listed below. This is form my masters project. Also in what way can I connect the filleted surfaces shown in fig by a weld or just load or stress transfer connection.

I am facing issues with my program. Listed below. This is form my masters project. Also in what way can I connect the filleted surfaces shown in fig by a weld or just load or stress transfer connection.

Code:

fini

/clear

/title,C160T2B70-1L

/prep7

et,1,shell181

r,1,2

mp,ex,1,1.85e5

mp,nuxy,1,0.3

type,1

mat,1

real,1

k,1,69,19,0

k,2,69,0,0

k,3,0,0,0

k,4,0,159,0

k,5,69,159,0

k,6,69,139,0

k,7,0,0,2500

k,8,71,19,0

k,9,71,0,0

k,10,139,0,0

k,11,139,159,0

k,12,71,159,0

k,13,71,139,0

k,14,139,0,2500

l,1,2

l,2,3

l,3,4

l,4,5

l,5,6

l,3,7

l,8,9

l,9,10

l,10,11

l,11,12

l,12,13

l,10,14

adrag,1,2,3,4,5,,6,,,,,,

adrag,7,8,9,10,11,,12,,,,,,

afillt,1,2,4

afillt,13,3,4

afillt,14,4,4

afillt,15,5,4

afillt,6,7,4

afillt,17,8,4

afillt,18,9,4

afillt,19,10,4

local,11,1,0,19.5,20,,,90

k,57,5,0

k,58,5,90

k,59,5,180

k,60,5,270

a,57,58,59,60

asba,3,10local,12,1,0,138.5,20,,,90

k,61,5,0

k,62,5,90

k,63,5,180

k,64,5,270

a,61,62,63,64

asba,19,3

local,13,1,0,138.5,2480,,,90

k,65,5,0

k,66,5,90

k,67,5,180

k,68,5,270

a,65,66,67,68

asba,10,3

local,14,1,0,19.5,2480,,,90

k,69,5,0

k,70,5,90

k,71,5,180

k,72,5,270

a,69,70,71,72

asba,19,3

local,15,1,139,19.5,20,,,90

k,73,5,0

k,74,5,90

k,75,5,180

k,76,5,270

a,73,74,75,76

asba,8,3

local,16,1,139,138.5,20,,,90

k,77,5,0

k,78,5,90

k,79,5,180

k,80,5,270

a,77,78,79,80

asba,19,3

local,17,1,139,138.5,2480,,,90

k,81,5,0

k,82,5,90

k,83,5,180

k,84,5,270

a,81,82,83,84

asba,8,3

local,18,1,139,19.5,2480,,,90

k,85,5,0

k,86,5,90

k,87,5,180

k,88,5,270

a,85,86,87,88

asba,19,3

csys,0

esize,5

amesh,all,,,

allsel

lsel,s,,,11

lsel,a,,,19

lsel,a,,,20

lsel,a,,,21

nsll,s,1

d,all,all,0

lsel,s,,,22

lsel,a,,,24

lsel,a,,,26

lsel,a,,,27

nsll,s,1

d,all,all,0

lsel,s,,,28

lsel,a,,,30

lsel,a,,,32

lsel,a,,,33

nsll,s,1

d,all,all,0

lsel,s,,,67

lsel,a,,,68

lsel,a,,,70

lsel,a,,,71

nsll,s,1

d,all,all,0lsel,s,,,79

lsel,a,,,80

lsel,a,,,81

lsel,a,,,82

nsll,s,1

d,all,all,0

lsel,s,,,75

lsel,a,,,76

lsel,a,,,77

lsel,a,,,78

nsll,s,1

d,all,all,0

lsel,s,,,83

lsel,a,,,84

lsel,a,,,85

lsel,a,,,86

nsll,s,1

d,all,all,0

lsel,s,,,87

lsel,a,,,88

lsel,a,,,89

lsel,a,,,90

nsll,s,1

d,all,all,0

nsel,s,loc,x,4,64

nsel,r,loc,y,0,0

nplot

nsel,r,loc,z,0,50

cm,N1,node

cmsel,s,N1

d,all,uy,0

allsel

nsel,s,loc,x,4,64

nsel,r,loc,y,0,0

nplot

nsel,r,loc,z,2450,2500

cm,N2,node

cmsel,s,N2

d,all,uy,0

allsel

nsel,s,loc,x,0,0

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,0,50

cm,N3,node

cmsel,s,N3

d,all,ux,0

allsel

nsel,s,loc,x,0,0

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,2450,2500

cm,N4,node

cmsel,s,N4

d,all,ux,0

allsel

nsel,s,loc,x,0,0

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,0,50

cm,N5,node

cmsel,s,N5

d,all,uY,0

allsel

nsel,s,loc,x,0,0

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,2450,2500

cm,N6,node

cmsel,s,N6

d,all,uY,0

allsel

nsel,s,loc,x,4,64

nsel,r,loc,y,158,158

nplot

nsel,r,loc,z,849,851

cm,N7,node

cmsel,s,N7,node

f,N7,fy,-0.01925

allsel

nsel,s,loc,x,4,64

nsel,r,loc,y,158,158

nplot

nsel,r,loc,z,1649,1651

cm,N8,node

cmsel,s,N8,node

f,N8,fy,-0.01925

allsel

nsel,s,loc,x,74,136

nsel,r,loc,y,0,0

nplot

nsel,r,loc,z,0,50

cm,N9,node

cmsel,s,N9

d,all,uy,0

allsel

nsel,s,loc,x,74,136

nsel,r,loc,y,0,0

nplot

nsel,r,loc,z,2450,2500

cm,N10,node

cmsel,s,N10

d,all,uy,0

allsel

nsel,s,loc,x,139,139

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,0,50

cm,N11,node

cmsel,s,N11

d,all,ux,0

allsel

nsel,s,loc,x,139,139

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,2450,2500

cm,N12,node

cmsel,s,N12

d,all,ux,0

allselnsel,s,loc,x,139,139

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,0,50

cm,N13,node

cmsel,s,N13

d,all,uY,0

allsel

nsel,s,loc,x,139,139

nsel,r,loc,y,0,158

nplot

nsel,r,loc,z,2450,2500

cm,N14,node

cmsel,s,N14

d,all,uY,0

allsel

nsel,s,loc,x,74,136

nsel,r,loc,y,158,158

nplot

nsel,r,loc,z,849,851

cm,N15,node

cmsel,s,N15,node

f,N7,fy,-0.01925

allsel

nsel,s,loc,x,74,136

nsel,r,loc,y,158,158

nplot

nsel,r,loc,z,1649,1651

cm,N16,node

cmsel,s,N16,node

f,N8,fy,-0.01925

allsel

/SOLU

PSTRES,ON

SOLVE

FINISH

/SOLU

ANTYPE,BUCKLE

OUTRES,ALL,ALL

BUCOPT,LANB,30

SOLVE

FINISH

/SOLU

EXPASS,ON

MXPAND,30,,,YES

OUTRES,ALL,ALL

SOLVE

FINISHAttachments

Last edited by a moderator: