- #1

engineeerm

- 1

- 0

Hello, I was searching on this forum for a long time, now I have a problem with my homework and I should complete this till tomorrow, I could use some hand :) Please somebody led me some light, and I believe this will be useful for others.

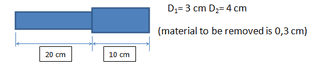

For a transmisson shaft (material : 304 stainless steel) shown in the figure below, using Sandvik website http://www.sandvik.coromant.com/en-gb , after selecting an appropriate insert and tool holder , calculate the following ,

1- Cutting speed, spindle speed , and feedrate, for longitudinal cutting

2- Power and torque required on the spindle

3- Cutting time

4- Tool life

5- Peak to valley roughness

Show in detail, the tables you have used from website and/or your book and explain your logic. Please indicate which insert and tool holder you have selected and why.

image upload no limit

Homework Statement

For a transmisson shaft (material : 304 stainless steel) shown in the figure below, using Sandvik website http://www.sandvik.coromant.com/en-gb , after selecting an appropriate insert and tool holder , calculate the following ,

1- Cutting speed, spindle speed , and feedrate, for longitudinal cutting

2- Power and torque required on the spindle

3- Cutting time

4- Tool life

5- Peak to valley roughness

Show in detail, the tables you have used from website and/or your book and explain your logic. Please indicate which insert and tool holder you have selected and why.

image upload no limit