- #1

Travis T

- 18

- 2

Hi, I'm sizing motor for a linear motion,

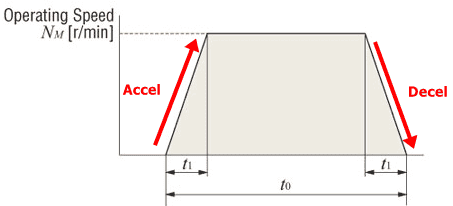

usually for the time distance graph would be looks like this,

however, how does the graph look like if the stroke is very short?

Example: velocity is 0.1m/s, acceleration is 1m/s2, moving stroke is 0.5mm, a cycle is within 0.05s

the application is to compensate positioning errors which is very small.

usually for the time distance graph would be looks like this,

however, how does the graph look like if the stroke is very short?

Example: velocity is 0.1m/s, acceleration is 1m/s2, moving stroke is 0.5mm, a cycle is within 0.05s

the application is to compensate positioning errors which is very small.