- #1

nuggetchris

- 5

- 0

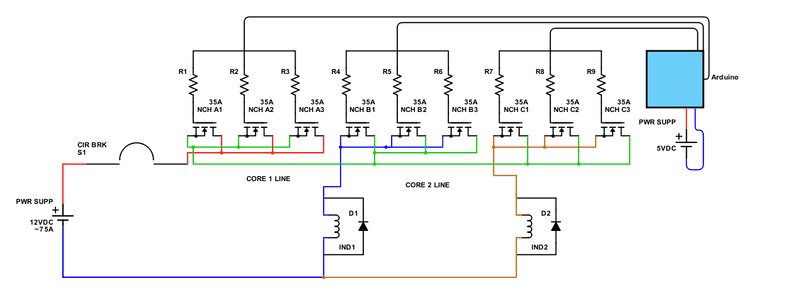

For a project, I need a means of switching a high-current circuit between two inductors. The purpose is, each inductor serves as an electromagnet, and they are switched every 15s or so in order for one of the two to cool before starting again. The system I've designed uses arduino as a controller and a couple of MOSFETs wired inline in order to electronically switch the circuit. The current delivered to each inductor should be around 75A at 12VDC. In this specific example, I used three 35A rated MOSFETS in each 'bank' which would function similar to a single relay. Here is the schematic:

Bank B of MOSFETs is a splice from green line to Bank C. The idea is that Bank A will act as a supply switch (Open = NO Power), Bank B (Closed = IND1 ON, IND2 OFF), Bank C (Closed = IND1 OFF, IND2 ON). **The supply switch acts to isolate IND2 from IND1** . To the contrary, with not having the supply switch and splice, the only way I could supply power to the second inductor is if I were also supplying it to the first. That is why I have included the leftmost *third* bank instead of a simple 2, since I need to bypass power past the first inductor.

I am asking for a few aspects:

1) I feel I need more diodes in the circuit to protect against kickback. Have the diodes been added in the right places?

2) Are all the connections correct for the switches and the circuit to function? (Specifically the MOSFET banks and Source/Drain)

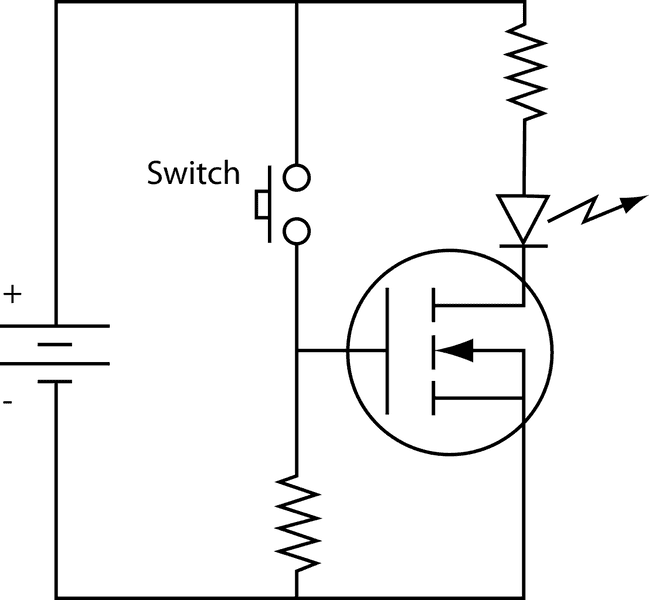

Here is an image I've found of an example NCH circuit:

It would appear from this image, that I *do* in fact have the connections of source and drain for each MOSFET wired correctly, with source on the positive end and drain on negative end. Please clarify if it is wrong.

3) Is there a solution to the issue of MOSFETs not turning on at the same VGS, leading to overload/explosion?

Bank B of MOSFETs is a splice from green line to Bank C. The idea is that Bank A will act as a supply switch (Open = NO Power), Bank B (Closed = IND1 ON, IND2 OFF), Bank C (Closed = IND1 OFF, IND2 ON). **The supply switch acts to isolate IND2 from IND1** . To the contrary, with not having the supply switch and splice, the only way I could supply power to the second inductor is if I were also supplying it to the first. That is why I have included the leftmost *third* bank instead of a simple 2, since I need to bypass power past the first inductor.

I am asking for a few aspects:

1) I feel I need more diodes in the circuit to protect against kickback. Have the diodes been added in the right places?

2) Are all the connections correct for the switches and the circuit to function? (Specifically the MOSFET banks and Source/Drain)

Here is an image I've found of an example NCH circuit:

It would appear from this image, that I *do* in fact have the connections of source and drain for each MOSFET wired correctly, with source on the positive end and drain on negative end. Please clarify if it is wrong.

3) Is there a solution to the issue of MOSFETs not turning on at the same VGS, leading to overload/explosion?