- #1

Sid55

- 26

- 1

Thanks to anyone who likes to chime in and help out this newbie.

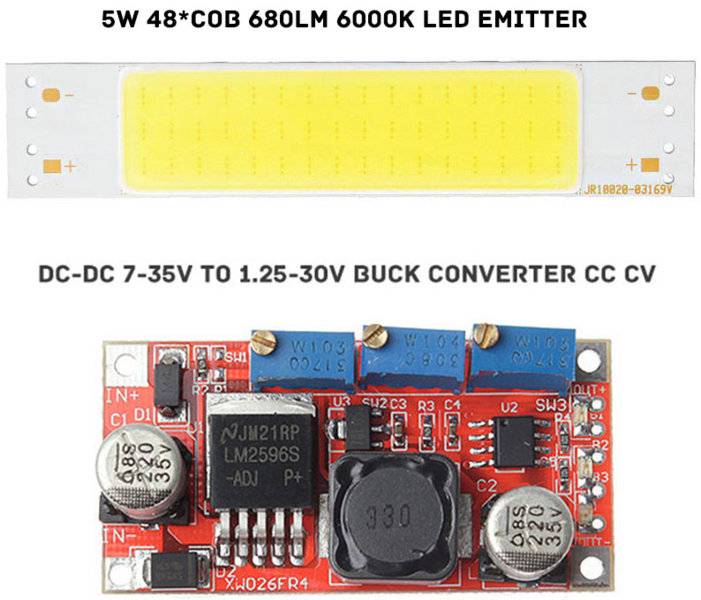

I bought some CC CV buck converters to power my DIY LED panel project using a perfectly working PC power supply unit that was collecting dust inside a fairly old and unused PC but unfortunately the buck converter does not output desired voltage to power up LED COB lights to their full potential.

My test set up:

* Load: 2 X 5 Watt LED COB lights (rated at 9 - 11V @ 400mA each) wired in parallel.

* DC power source: 12V (480 Watt max PC PSU)

* DC-DC 7-35V to 1.25-30V buck converter CC CV (15W max output, conversion efficiency @92%)

Test results under load when wired in parallel:

* Output voltage from buck converter drops to about 8.5V which is not adequate at all

* Output current from buck converter is just over 900mA which is more than adequate for both

* LED COB lights appear a lot dimmer compared to when powered with 11V battery pack without the buck converter

Questions:

* How to raise voltage output from the buck converter while limiting output current ?

* Should I use a much higher wattage CC CV boost converter instead ?

* Can any other arrangement be worked out ?

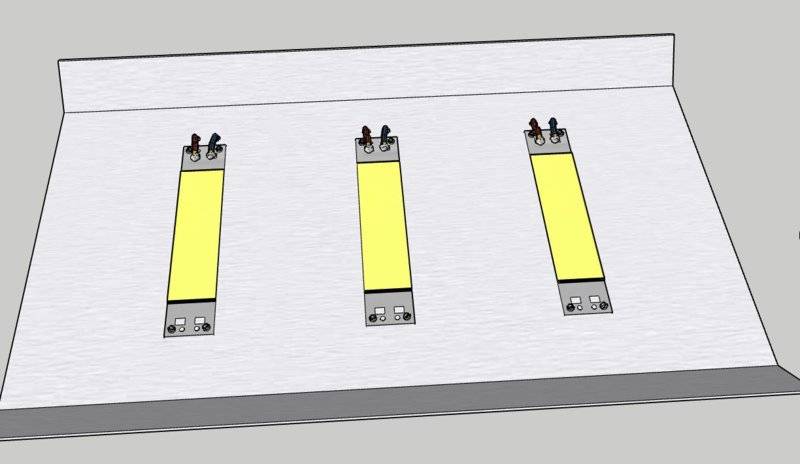

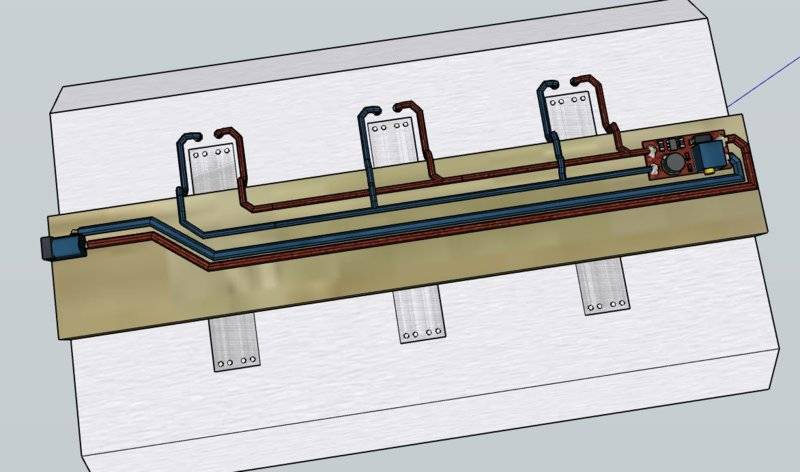

The ultimate goal is to power up the LED panel with 3 LED COB lights at 10-11V @400-450mA each

I bought some CC CV buck converters to power my DIY LED panel project using a perfectly working PC power supply unit that was collecting dust inside a fairly old and unused PC but unfortunately the buck converter does not output desired voltage to power up LED COB lights to their full potential.

My test set up:

* Load: 2 X 5 Watt LED COB lights (rated at 9 - 11V @ 400mA each) wired in parallel.

* DC power source: 12V (480 Watt max PC PSU)

* DC-DC 7-35V to 1.25-30V buck converter CC CV (15W max output, conversion efficiency @92%)

Test results under load when wired in parallel:

* Output voltage from buck converter drops to about 8.5V which is not adequate at all

* Output current from buck converter is just over 900mA which is more than adequate for both

* LED COB lights appear a lot dimmer compared to when powered with 11V battery pack without the buck converter

Questions:

* How to raise voltage output from the buck converter while limiting output current ?

* Should I use a much higher wattage CC CV boost converter instead ?

* Can any other arrangement be worked out ?

The ultimate goal is to power up the LED panel with 3 LED COB lights at 10-11V @400-450mA each