- #1

Mech_LS24

- 148

- 16

- TL;DR Summary

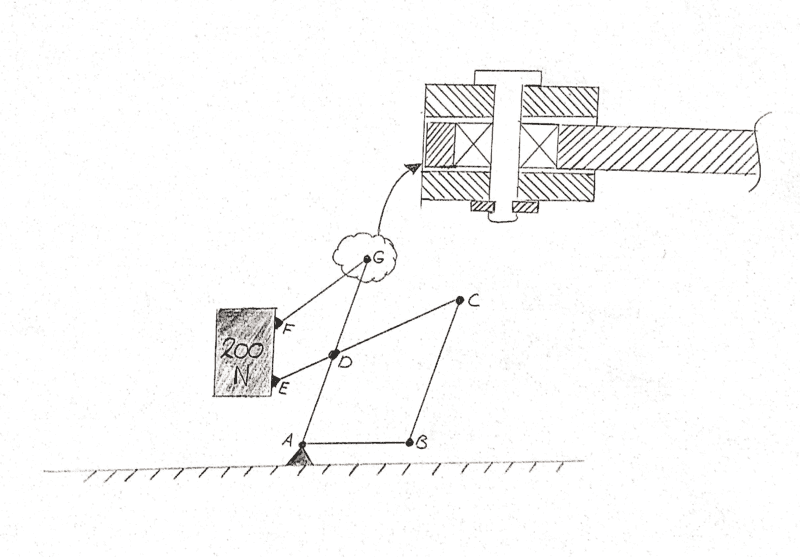

- In a structure with 5 pivot points and provided with deep groove ball bearings. I want to calculate the losses due to friction.

Hello,

I have a structure with 5 pivot point and those are provided with deep groove ball bearings (see sketch).

Calculation for friction losses (deep grove ball bearing):

Parameters:

- Number of pivot points: 5

- Friction coefficient: 0.0010 - 0.0015 (Reference)

Total friction in the structure: 5*0.0015*100% = 0.75%

If compared to plain bearings:

Calculation for friction losses (plain bearing):

- Number of pivot points: 5

- Friction coefficient: 0.2 (worst case, Reference)

Total friction in the structure: 5*0.2*100% = 100%

I already imagined that a plain bearing has a higher impact on friction, but this amount does surprises me. Are those assumptions and calculations done in a correct manner? Or do I miss something here?

Besides, that 100% for plain bearings doesn't seem to be realistic. Does it mean the structure can't operate/move because the it can't 'overcome' the friction?

I have a structure with 5 pivot point and those are provided with deep groove ball bearings (see sketch).

Calculation for friction losses (deep grove ball bearing):

Parameters:

- Number of pivot points: 5

- Friction coefficient: 0.0010 - 0.0015 (Reference)

Total friction in the structure: 5*0.0015*100% = 0.75%

If compared to plain bearings:

Calculation for friction losses (plain bearing):

- Number of pivot points: 5

- Friction coefficient: 0.2 (worst case, Reference)

Total friction in the structure: 5*0.2*100% = 100%

I already imagined that a plain bearing has a higher impact on friction, but this amount does surprises me. Are those assumptions and calculations done in a correct manner? Or do I miss something here?

Besides, that 100% for plain bearings doesn't seem to be realistic. Does it mean the structure can't operate/move because the it can't 'overcome' the friction?