- #1

Mechanic7

- 3

- 0

Hello all,

I'm a Mechanical engineer with no prior experience in designing flow systems.

I'm struggling with a hydraulic system that I have to design.

the number of unknowns is large. but maybe by dividing the system to small sections, a solution can be found.

I attached a schematic drawing to the thread,as well as some pages from a fluid mechanics book I have, and on which I rely in my calculations.

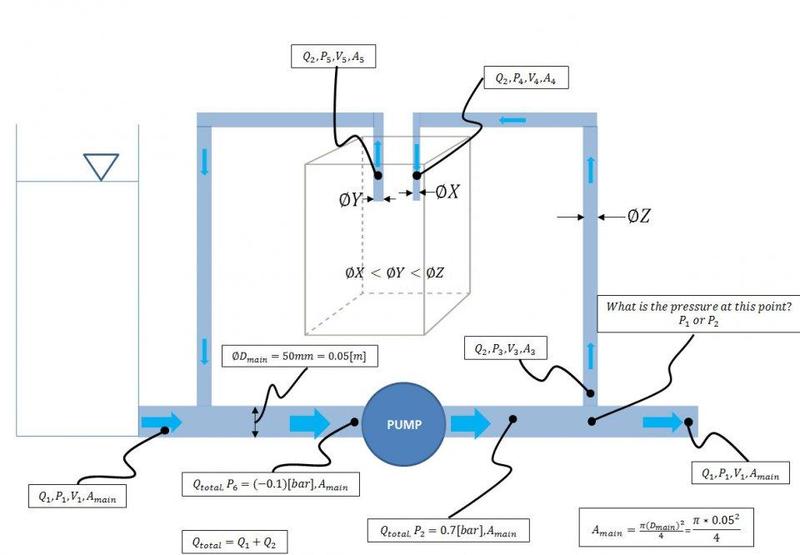

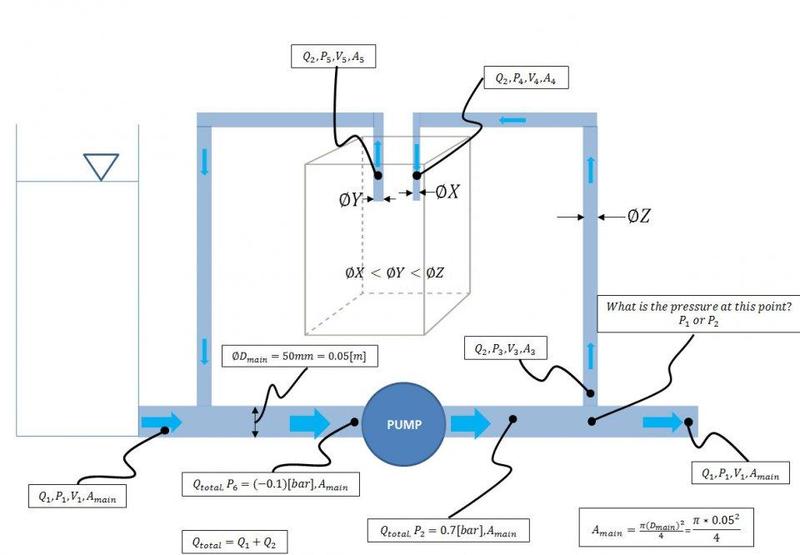

Basically, I need to design and optimize a system that will circulate water in 2 pipes.

first, I need the water to flow out of a reservoir, through a ∅50mm pipe.

the water then enter a pump.

Volume flow through the pump is 160 [liter/min].

after the pump there is a junction.

Most of the water will continue to the rest of the system (lower right section in the drawing) and return to the reservoir,

but a small percentage of the water will have to flow through a narrower pipe (with an unknown diameter ∅Z)

This pipe will eventually converge at its end, in order to increase the speed of the water, flowing into the box shown on the top. at this convergence the pipe diameter should be ∅X (∅X<∅Z).

the box is actually a rectangular prism, not open to atmosphere.

its cross-section size is about 20x20mm, and the height is about 80mm.

Conditions in the prism should be:

∅Y and then diverge back to the same pipe diameter before the box (e.g. ∅Z). this means ∅X<∅Y<∅Z.

After the water flows out of the box it has to flow towards the main line (∅50mm) and back into the pump,

and vise versa.

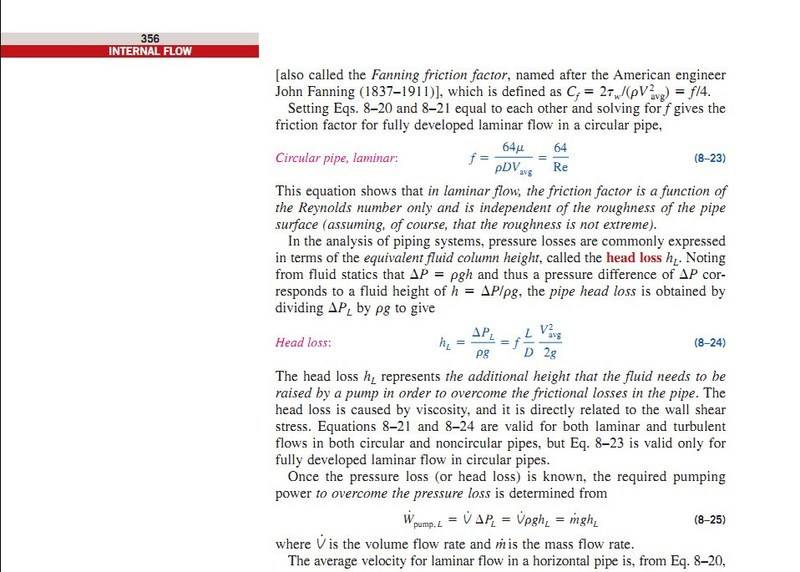

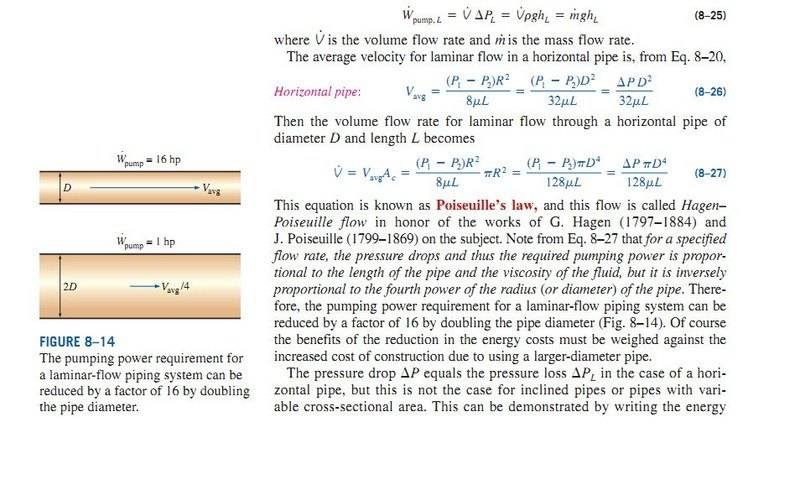

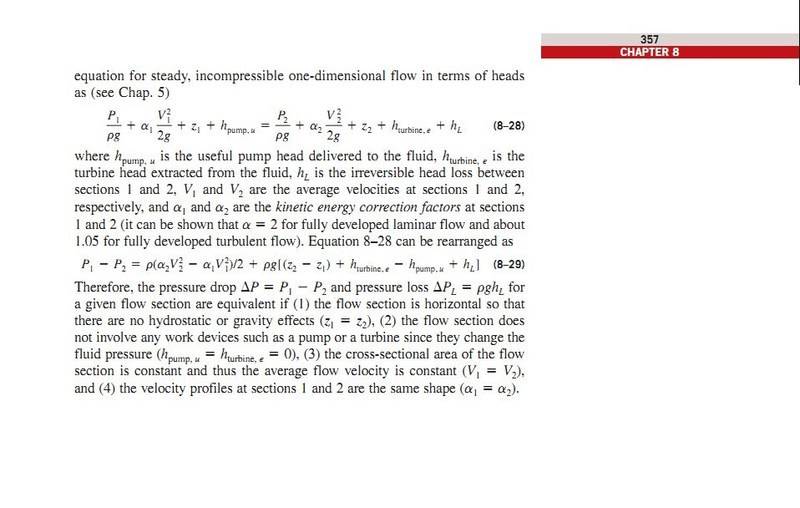

I know that I should probably use the Bernoulli equation and take into account losses (using Darcy-Weisbach friction factor)

I find it very confusing to understand where to use [ΔP] and where to use [ΔP loss] (these 2 terms show in the pages I attached)

the givens are:

Total flow rate: 160 [liter/min]

Pressure before the pump: (-0.1)[bar]

pressure after the pump: 0.7[bar]

main line diameter: ∅50mm

especially I would like to know the volume flows, pressures, water speed at all the points I marked in the smaller pipe. and of course the required diameters, including the ones in the convergence and divergence inside the box.

There is also 1 more question I wrote on the drawing itself.

I can't seem to understand where to start solving this problem and will appreciate any help you can offer.

Thanks a lot in advance!

I'm a Mechanical engineer with no prior experience in designing flow systems.

I'm struggling with a hydraulic system that I have to design.

the number of unknowns is large. but maybe by dividing the system to small sections, a solution can be found.

I attached a schematic drawing to the thread,as well as some pages from a fluid mechanics book I have, and on which I rely in my calculations.

Basically, I need to design and optimize a system that will circulate water in 2 pipes.

first, I need the water to flow out of a reservoir, through a ∅50mm pipe.

the water then enter a pump.

Volume flow through the pump is 160 [liter/min].

after the pump there is a junction.

Most of the water will continue to the rest of the system (lower right section in the drawing) and return to the reservoir,

but a small percentage of the water will have to flow through a narrower pipe (with an unknown diameter ∅Z)

This pipe will eventually converge at its end, in order to increase the speed of the water, flowing into the box shown on the top. at this convergence the pipe diameter should be ∅X (∅X<∅Z).

the box is actually a rectangular prism, not open to atmosphere.

its cross-section size is about 20x20mm, and the height is about 80mm.

Conditions in the prism should be:

- Water flow - between 0.5 [liter/min] to 5 [liter/min]

- Formation of air bubbles should be as low as possible (clear flow).

- Water should fill the entire box, without dead regions (would love to hear what you think about that possibility considering the current design - is it possible to achieve? do I need turbulent or laminar flow for that? )

∅Y and then diverge back to the same pipe diameter before the box (e.g. ∅Z). this means ∅X<∅Y<∅Z.

After the water flows out of the box it has to flow towards the main line (∅50mm) and back into the pump,

and vise versa.

I know that I should probably use the Bernoulli equation and take into account losses (using Darcy-Weisbach friction factor)

I find it very confusing to understand where to use [ΔP] and where to use [ΔP loss] (these 2 terms show in the pages I attached)

the givens are:

Total flow rate: 160 [liter/min]

Pressure before the pump: (-0.1)[bar]

pressure after the pump: 0.7[bar]

main line diameter: ∅50mm

especially I would like to know the volume flows, pressures, water speed at all the points I marked in the smaller pipe. and of course the required diameters, including the ones in the convergence and divergence inside the box.

There is also 1 more question I wrote on the drawing itself.

I can't seem to understand where to start solving this problem and will appreciate any help you can offer.

Thanks a lot in advance!