- #1

goonking

- 434

- 3

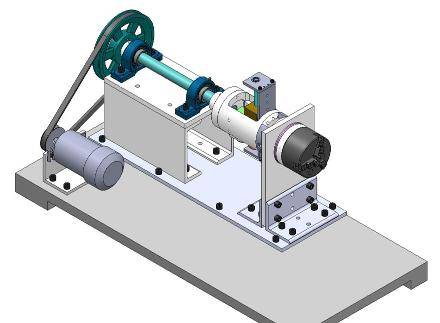

A pulley-and-shaft is connected to a motor which applies torque to spin the pulley as shown below:

Now imagine someone jams machine by sticking a broom into one of the holes of the pulley.

I would imagine there would be normal stresses at the hole (location of jam) and torsional stress on the shaft (from the motor attempting to continue turning), but magnitudes of these stresses would depend on factors like radius of the shaft, distance of holes from the center of the pulley, length of shaft, etc.

Are my assumptions reasonable?

Now imagine someone jams machine by sticking a broom into one of the holes of the pulley.

I would imagine there would be normal stresses at the hole (location of jam) and torsional stress on the shaft (from the motor attempting to continue turning), but magnitudes of these stresses would depend on factors like radius of the shaft, distance of holes from the center of the pulley, length of shaft, etc.

Are my assumptions reasonable?