- #1

Chandrasekar

- 13

- 1

- TL;DR Summary

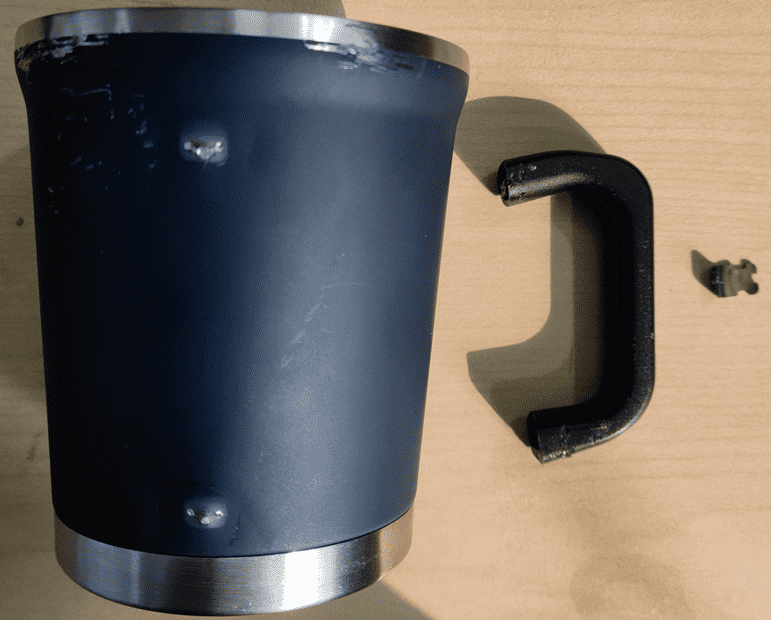

- How to join a plastic part with a metal part?

i have a plastic handle and want to join it with a metal body. i can join it with heat stacking method i have find a product who done done that.

is there any other way to join permenently?

is there any other way to join permenently?