- #1

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

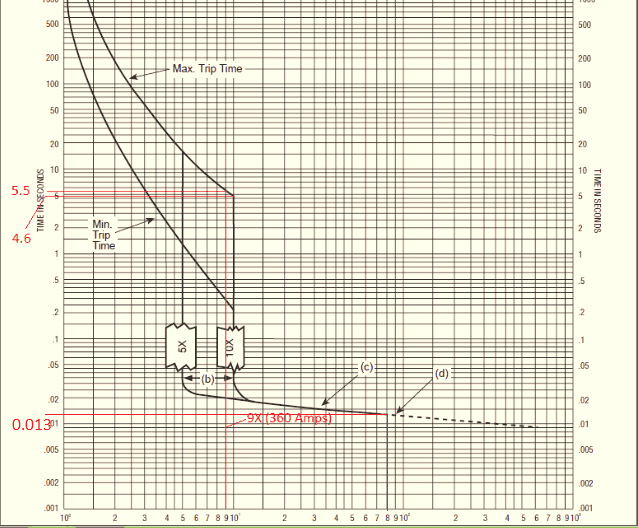

In summary, the conversation discussed the maximum interrupting time of FW/HFW Molded-Case Circuit Breakers and how to read the attached time-current curves. The curves show the coordination between different elements and help determine the maximum instantaneous fault clearing time. The MCCB data provided includes a thermal range, magnetic range, and horizontal axis which is based on multiples of the current setting. The discussion also touched on selecting the appropriate magnetic setting to protect a motor and the importance of ensuring the breaker eventually trips to prevent the motor from overheating. Finally, the conversation mentioned the importance of considering the LRA and the potential heat that may be generated in a locked rotor situation.

Engineering news on Phys.org

- #2

zoki85

- 1,198

- 230

What seems to be problem? Max. interrupting time vs multiple of the nominal current curve is given in the graph. Just read it.

You need to know only the rated (nominal) current of the breaker.

You need to know only the rated (nominal) current of the breaker.

- #3

anorlunda

Staff Emeritus

- 11,308

- 8,732

Isn't there a spec sheet for that specific model?

- #4

Windadct

- 1,452

- 411

The Max time is the curve(line) - for any current level you then have to find the corresponding point on the curve. However - these curves are most useful when you superimpose the various elements onto one curve, you can then see the coordination between the various elements. For example -- if there are up stream fuses they will have a similar Time Curve - you would want the down stream items ( cables, motors) to be protected by this device and ideally not the fuses.

- #5

Adecypher

- 3

- 0

Windadct said:The Max time is the curve(line) - for any current level you then have to find the corresponding point on the curve. However - these curves are most useful when you superimpose the various elements onto one curve, you can then see the coordination between the various elements. For example -- if there are up stream fuses they will have a similar Time Curve - you would want the down stream items ( cables, motors) to be protected by this device and ideally not the fuses.

Thanks

I have MCCB data as follows:

MCCB Rating = 40 Amps (i.e. Maximum Continuous Ampere Rating at 40 degree C)

Thermal Range = 32 - 40 Amps

Magnetic Range = 200 - 400 Amps (i.e. Instantaneous Pickup Range)

Horizontal axis = Multiple of current setting (i.e. Multiples of 40 Amps - Breaking Rating).

Based on this info, what will be the maximum instantaneous fault clearing time (secs)?

I came up with:

1) 5.5 secs corresponds to 10X (400 Amps)

2) 4.6 secs corresponds to 9X (360 Amps)

which one of the above two values in (secs) are close to being correct or else?

Note: Not to confuse you regarding 9X (360 Amps) value I choose in the graph.

I selected 9X because I selected this MCCB to protect a Motor whose Lock Rotor Current = 143 Amps, the Service Factor of this Motor is 1.0, therefore I used 360 Amps magnetic setting > (2.5 X LRC) = 357. 5 Amps.

Regards

Attachments

- #6

Windadct

- 1,452

- 411

Does 5.5 Sec sound like it is instantaneous? Not mocking your post - but asking you to think about the info. The Long time will be for general overloads and often based around 3 to 5 x the FLA. ( It has been a while since I did these) - however you need to ensure that even at 150% the breaker will eventually trip to prevent the motor from overheating. Smaller motors the shorter the time they can be in overload.

As for the instantaneous(see note below) - you need to make sure that the LRA hits that part of the curve, but noting some motors ( particularly high efficiency) can hit LRA on hard line starts.

The motor OEM will often provide the same format time current curve to help with this coordination.

Often the Locked Rotor coordination really is referred to a Short Time (not instantaneous) - in general terms Long Time is for Motor overload, Short time ( locked / seized motor) has a small fixed amount of time to allow for starts, and true Instantaneous is for electrical short circuits / faults ( so there is no intentional time delay on the trip).

As for the instantaneous(see note below) - you need to make sure that the LRA hits that part of the curve, but noting some motors ( particularly high efficiency) can hit LRA on hard line starts.

The motor OEM will often provide the same format time current curve to help with this coordination.

Often the Locked Rotor coordination really is referred to a Short Time (not instantaneous) - in general terms Long Time is for Motor overload, Short time ( locked / seized motor) has a small fixed amount of time to allow for starts, and true Instantaneous is for electrical short circuits / faults ( so there is no intentional time delay on the trip).

- #7

Adecypher

- 3

- 0

@ Windadct LOL you are right it is not "instantaneous"; I have attached another curve with 0.013 Amps as Inst current shown; actually you can conservatively choose 0.016 Amps around the slope region (which is the instantaneous region of operation of this breaker).

- #8

Windadct

- 1,452

- 411

So you mean 0.013 Seconds ? Wont that be at 80X or 3200A.. as you pulled the line out. --

If the LRA is 143A = 3.6X ( of the 40A) --- as I read this you are up to 40 Secconds - a small motor like this probably can not survive 40 Sec locked rotor. Another way to think of this for a 480V 3PH motor...( 143 x 480 x Srt(3) )= 119 KW of heat ! being dumped into the windings of the motor!...

I would only want LRA to exist for 1-2 Seconds at most in a typical application.

If the LRA is 143A = 3.6X ( of the 40A) --- as I read this you are up to 40 Secconds - a small motor like this probably can not survive 40 Sec locked rotor. Another way to think of this for a 480V 3PH motor...( 143 x 480 x Srt(3) )= 119 KW of heat ! being dumped into the windings of the motor!...

I would only want LRA to exist for 1-2 Seconds at most in a typical application.

1. What is maximum interrupting time for HFW breakers?

The maximum interrupting time for HFW (high-frequency withstand) breakers is the amount of time it takes for the breaker to open and interrupt the flow of current in the event of a fault or overload. This time is typically measured in milliseconds.

2. How is maximum interrupting time determined for HFW breakers?

The maximum interrupting time for HFW breakers is determined through rigorous testing and certification processes. These tests involve subjecting the breaker to various fault conditions and measuring the time it takes for it to open and interrupt the current flow. The results of these tests determine the maximum interrupting time for the breaker.

3. Why is maximum interrupting time important for HFW breakers?

Maximum interrupting time is important for HFW breakers because it determines the safety and reliability of the breaker. In the event of a fault or overload, the breaker must be able to open and interrupt the current flow quickly to prevent damage to the electrical system or potential hazards for people and equipment.

4. What factors can affect the maximum interrupting time for HFW breakers?

The maximum interrupting time for HFW breakers can be affected by various factors, including the type of fault, the current level, and the condition of the breaker's components. Environmental factors such as temperature and humidity can also impact the performance of the breaker and its maximum interrupting time.

5. How can the maximum interrupting time for HFW breakers be improved?

The maximum interrupting time for HFW breakers can be improved by using advanced technologies and materials in the design and manufacturing of the breaker. Regular maintenance and testing can also help ensure that the breaker is operating at its optimal performance and can interrupt the current flow quickly and efficiently when needed.

Similar threads

-

Electrical Engineering

- Replies

- 8

- Views

- 847

-

Electrical Engineering

- Replies

- 23

- Views

- 3K

-

Electrical Engineering

- Replies

- 5

- Views

- 945

-

Electrical Engineering

- Replies

- 7

- Views

- 1K

-

Electrical Engineering

- Replies

- 19

- Views

- 629

-

Electrical Engineering

- Replies

- 5

- Views

- 1K

- Replies

- 42

- Views

- 3K

-

Electrical Engineering

- Replies

- 12

- Views

- 1K

-

Electrical Engineering

- Replies

- 24

- Views

- 4K

-

Electrical Engineering

- Replies

- 8

- Views

- 1K

Share: