- #1

RedneckPhysics

- 7

- 0

- TL;DR Summary

- (Unsure of where to post) Trying to determine (semi-quantitatively), the amount of water flow needed to clear away bubbles in a 2-material, sharp-cornered micro-fluidic channel.

Hi All,

I need some help to figure out how to best go about setting-up and analyzing a micro-fluidics design problem I ran across in my research. It's not the typical single-surface contact angle adhesion kind of analysis.

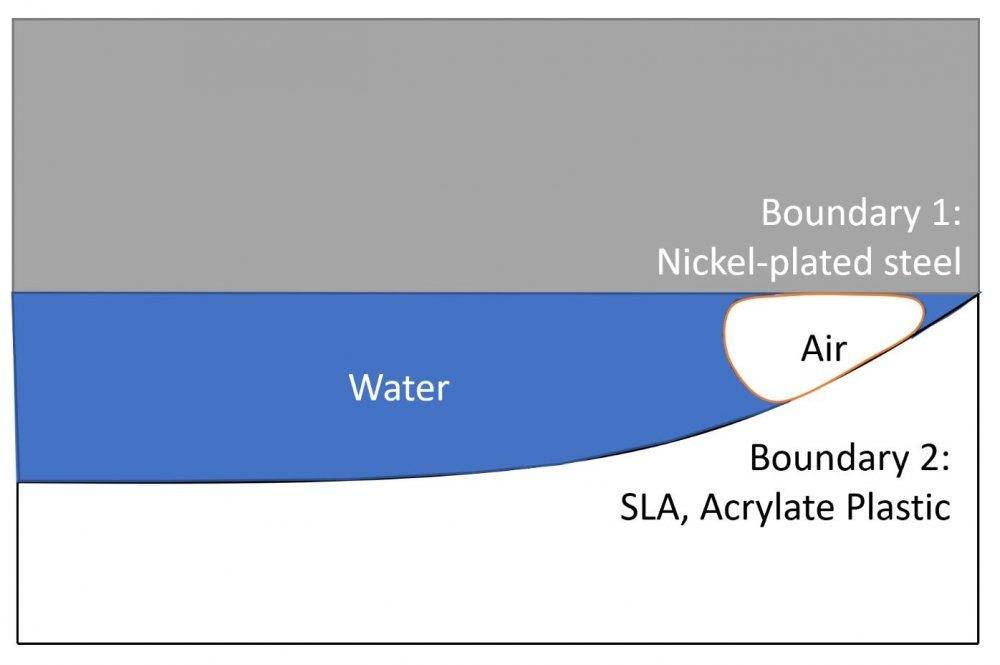

Basically, I have a wide micro-fluidic channel that's formed by a nickel-plated metal transducer surface on the top wall, and a 3D printed acrylate plastic part for the bottom wall, with a very gradually sloping fillet forming the side walls. The part starts empty (air-filled), and water is pumped through the channel, ideally displacing all of the air inside (in other words, fills the entire channel with water). The channel may not be fully wet-able, leaving behind pockets of air, or bubbles in the corners. Bubbles will inevitably be formed within the water circuit, and passed through this channel, and could be lodged inside. I expect the flow rate in the corners to be far lower than the center, due to the boundary effect, combined with the inlet and outlet geometry.

Basic dimensions aren't drawn... the full channel is approximately 0.5mm in height (boundary 1 to boundary 2, at the widest part in this diagram), and about 8mm wide in total. The radius of curvature on that fillet as-is varies between 3mm and 0.5mm.

Here's a simple cross section diagram of the right 1/2 of the channel (Water flow is into or out of the page):

I'm trying to get a sense of how this design will trap or expel any air bubbles, at some specified average flow rate. I'm guessing we can assume flow is laminar through the majority of the channel. I'll use that information to optimize the average radius of curvature on that fillet, or otherwise alter the shape of the channel. The channel can't just be a simple rectangular shape... it will need at a minimum of a circular 0.5mm radius fillet on the right wall. The more material in that fillet, the better, in this use case.

Also, how would changes in effective surface energy of each material influence bubble retention? My intuition says, wetability might be a plus in this case... basically decreasing the amount of gas in the bubble in contact with the 2 solid interfaces.

I'm wondering if surface etching, or micro-patterning or the like could positively influence bubble clearing. Or, in the opposite case, smoothing and polishing.

The outlet is situated at the bottom center of the channel, and water flows from the ends of the channel, towards the center. To successfully clear a bubble from the system, it will need to be pulled away from the wall, towards the center of the channel. The side walls near the outlet area aren't going to see much flow... but that's a different ball of wax (or bubble of gas), best saved for another day.

In setting up the analysis, my best guess at the problem's end goal, is to obtain the work required to separate an air bubble from the edge of the channel, and then, to minimize that. Or perhaps, just get the overall adhesion force instead, if that's easy to calculate?

Aside from that, my best guess at a starting point is with Young's relations, and approximating the curved surface as locally flat for simplicity's sake.

Perhaps it's a lot more simple than that? In the end, I just need to know if there's a design that's more conducive to clearing away bubbles, and not trapping them in the first place.

Any thoughts? I'm a bit overwhelmed when it comes to connecting the dots.

Thanks for your help!

Michael

Edit: 04/28/20 Re-uploaded diagram

I need some help to figure out how to best go about setting-up and analyzing a micro-fluidics design problem I ran across in my research. It's not the typical single-surface contact angle adhesion kind of analysis.

Basically, I have a wide micro-fluidic channel that's formed by a nickel-plated metal transducer surface on the top wall, and a 3D printed acrylate plastic part for the bottom wall, with a very gradually sloping fillet forming the side walls. The part starts empty (air-filled), and water is pumped through the channel, ideally displacing all of the air inside (in other words, fills the entire channel with water). The channel may not be fully wet-able, leaving behind pockets of air, or bubbles in the corners. Bubbles will inevitably be formed within the water circuit, and passed through this channel, and could be lodged inside. I expect the flow rate in the corners to be far lower than the center, due to the boundary effect, combined with the inlet and outlet geometry.

Basic dimensions aren't drawn... the full channel is approximately 0.5mm in height (boundary 1 to boundary 2, at the widest part in this diagram), and about 8mm wide in total. The radius of curvature on that fillet as-is varies between 3mm and 0.5mm.

Here's a simple cross section diagram of the right 1/2 of the channel (Water flow is into or out of the page):

I'm trying to get a sense of how this design will trap or expel any air bubbles, at some specified average flow rate. I'm guessing we can assume flow is laminar through the majority of the channel. I'll use that information to optimize the average radius of curvature on that fillet, or otherwise alter the shape of the channel. The channel can't just be a simple rectangular shape... it will need at a minimum of a circular 0.5mm radius fillet on the right wall. The more material in that fillet, the better, in this use case.

Also, how would changes in effective surface energy of each material influence bubble retention? My intuition says, wetability might be a plus in this case... basically decreasing the amount of gas in the bubble in contact with the 2 solid interfaces.

I'm wondering if surface etching, or micro-patterning or the like could positively influence bubble clearing. Or, in the opposite case, smoothing and polishing.

The outlet is situated at the bottom center of the channel, and water flows from the ends of the channel, towards the center. To successfully clear a bubble from the system, it will need to be pulled away from the wall, towards the center of the channel. The side walls near the outlet area aren't going to see much flow... but that's a different ball of wax (or bubble of gas), best saved for another day.

In setting up the analysis, my best guess at the problem's end goal, is to obtain the work required to separate an air bubble from the edge of the channel, and then, to minimize that. Or perhaps, just get the overall adhesion force instead, if that's easy to calculate?

Aside from that, my best guess at a starting point is with Young's relations, and approximating the curved surface as locally flat for simplicity's sake.

Perhaps it's a lot more simple than that? In the end, I just need to know if there's a design that's more conducive to clearing away bubbles, and not trapping them in the first place.

Any thoughts? I'm a bit overwhelmed when it comes to connecting the dots.

Thanks for your help!

Michael

Edit: 04/28/20 Re-uploaded diagram

Last edited: