- #1

Meneer

- 2

- 0

- TL;DR Summary

- Need help to correctly calculate the head loss and flow rate of a small PHES, so the turbine output power can be calculated.

Hello!

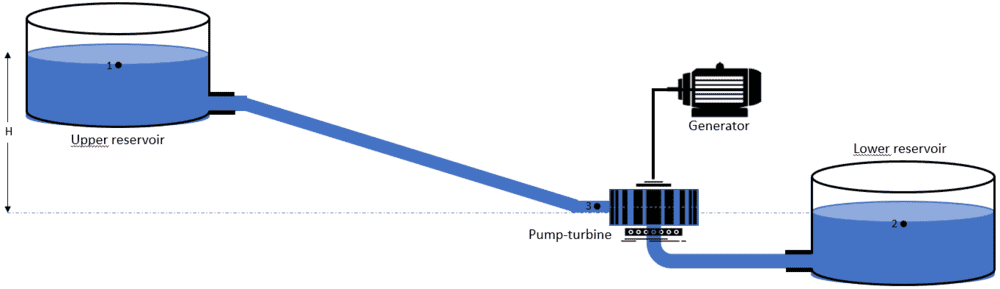

I am trying to model a small pumped hydro energy storage system, with two closed reservoirs (upper and lower).

However, I am assuming here that I only know the volume of both reservoirs, the penstock diameter and length, the height difference between both reservoirs, and the turbine efficiency. The fluid used is water.

This picture hopefully clarifies what I mean:

To determine the power output of the turbine I use P=ρ g Q η (H - Hlosses).

Therefore I would need to calculate both the flow rate Q and Hlosses

To calculate the flow rate Q , I was planning on using the Bernoulli equation between point 1 and 2 on the image, so I can assume P1 ,P2 , v1 and v2 are 0.

This would simplify the Bernoulli equation from P1/ρ + (V12)/2g + h1 = P2/ρ + (V22)/2g + h2 + Hlosses to 0 + 0 + H = 0 + 0 + 0 + Hlosses.

With the Darcy Weisbach equation (assuming no minor losses for now) I would then put this in terms of H = (f) (L/D) (v2/2g) .

with unknowns v and f, the Moody diagram and an iterative process can be used to determine both these factors.

The the flow rate is calculated by Q=V*A

However, I am not sure if this is a correct way of doing this, since I really need the flow velocity at point 3, as here the flow goes into the turbine. Also, from how I understand it now, if I do it like this the Head losses will be as large as the gross head which does not make sense.

Can someone please shed some light on this and help me in the right direction? Thank you!

I am trying to model a small pumped hydro energy storage system, with two closed reservoirs (upper and lower).

However, I am assuming here that I only know the volume of both reservoirs, the penstock diameter and length, the height difference between both reservoirs, and the turbine efficiency. The fluid used is water.

This picture hopefully clarifies what I mean:

To determine the power output of the turbine I use P=ρ g Q η (H - Hlosses).

Therefore I would need to calculate both the flow rate Q and Hlosses

To calculate the flow rate Q , I was planning on using the Bernoulli equation between point 1 and 2 on the image, so I can assume P1 ,P2 , v1 and v2 are 0.

This would simplify the Bernoulli equation from P1/ρ + (V12)/2g + h1 = P2/ρ + (V22)/2g + h2 + Hlosses to 0 + 0 + H = 0 + 0 + 0 + Hlosses.

With the Darcy Weisbach equation (assuming no minor losses for now) I would then put this in terms of H = (f) (L/D) (v2/2g) .

with unknowns v and f, the Moody diagram and an iterative process can be used to determine both these factors.

The the flow rate is calculated by Q=V*A

However, I am not sure if this is a correct way of doing this, since I really need the flow velocity at point 3, as here the flow goes into the turbine. Also, from how I understand it now, if I do it like this the Head losses will be as large as the gross head which does not make sense.

Can someone please shed some light on this and help me in the right direction? Thank you!