- #1

Herbid

- 14

- 0

Dear All Masters

I have problem with slewing bearing crane.

My subcon made a crane that have a very high platform deck form slewing bearing.

They said it is fine and the height is not an issue as it is in lower place.

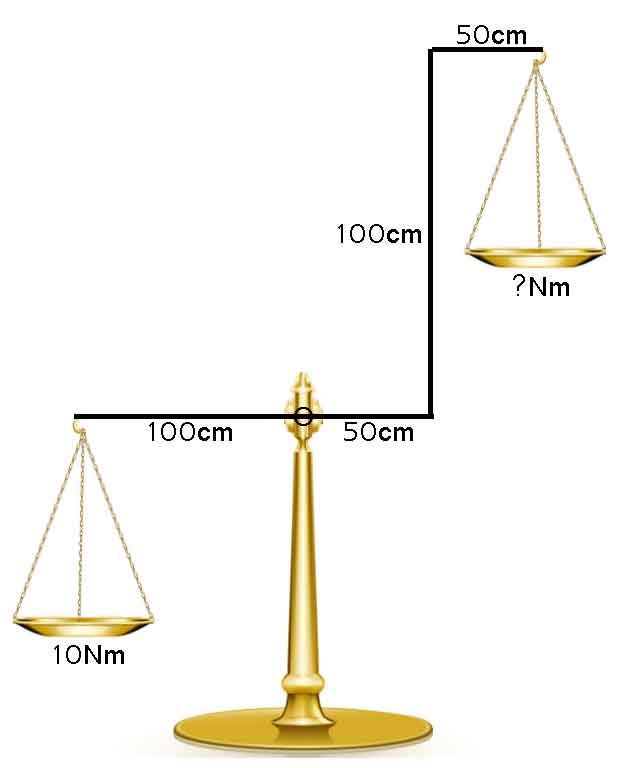

I know the higher the load from slewing bearing,

the bigger the force or moment works on it, especially in radial force,

like my pic attach.

But I don't know how to calculate the increasing of a radial force / moment that works physically.

Anyone can help?

Thanks.

I have problem with slewing bearing crane.

My subcon made a crane that have a very high platform deck form slewing bearing.

They said it is fine and the height is not an issue as it is in lower place.

I know the higher the load from slewing bearing,

the bigger the force or moment works on it, especially in radial force,

like my pic attach.

But I don't know how to calculate the increasing of a radial force / moment that works physically.

Anyone can help?

Thanks.