- #1

PhysicsTruth

- 117

- 18

- Homework Statement

- Construct a LED driver with ##K_P=10## for -0.2 - 0.2 V input. Correct it to 0-4V using an offset bias.

- Relevant Equations

- Using the LED Driver Circuit equation -

##V_{control} = V_{LED/anode} - V_{Th}##

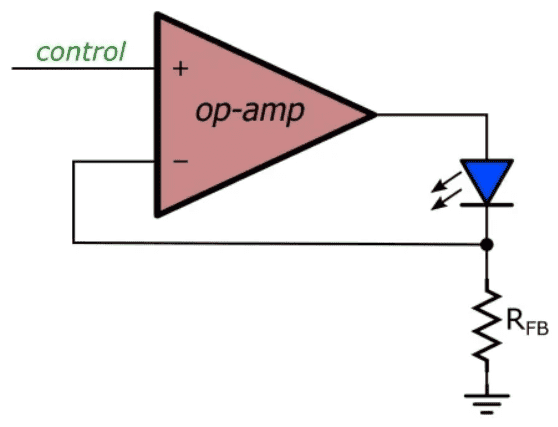

I have a proportional-only controller LED driver circuit -

I need to fine-tune its ##K_P## to 10 for a significant input of -0.2 to 0.2 V in the steady state. In that case, should I use a potentiometer with 10:1 setting? The LED (actuator) can drive voltages between 0 to 4V, so I need to add a resistor bias offset voltage to the controller as well. Can someone help me in these? I know that I need to utilize the Thevenin circuit, so should I just make a resistor bias from my positive rail supply to ground? Cam someone help me out?

I need to fine-tune its ##K_P## to 10 for a significant input of -0.2 to 0.2 V in the steady state. In that case, should I use a potentiometer with 10:1 setting? The LED (actuator) can drive voltages between 0 to 4V, so I need to add a resistor bias offset voltage to the controller as well. Can someone help me in these? I know that I need to utilize the Thevenin circuit, so should I just make a resistor bias from my positive rail supply to ground? Cam someone help me out?