- #1

Paul Chen

- 3

- 0

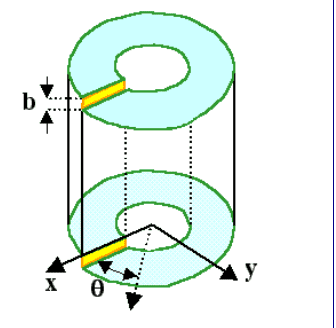

Consider a screw dislocation,

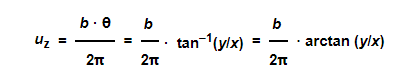

The displacement field is given by

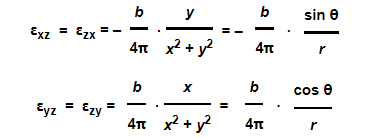

And the strain field is derived by

My question is that the displacement seems discontinuous across the dislocation surface (y=0, i.e., displacement jump from 0 to b), so why it is still differentiable on the surface and why the strain is continuous across the dislocation surface?

The displacement field is given by

And the strain field is derived by

My question is that the displacement seems discontinuous across the dislocation surface (y=0, i.e., displacement jump from 0 to b), so why it is still differentiable on the surface and why the strain is continuous across the dislocation surface?