- #1

DTM

- 73

- 9

- TL;DR Summary

- Following the formula for von Mises stress, can you give an intuitive explanation of why the von Mises stress may go down when the minor principal stress goes up.

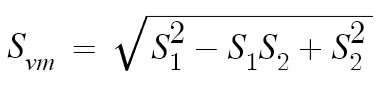

The formula for von Mises stress for a plane stress (2d) condition with no shear stress is:

So if S1 = 1000, S2 = 0 , then Svm = 1000.

If the S2 is now increased from 0 to 500. The von Mises stress will go from 1000 to 866

I understand this is how the equation works, but can someone give me an intuitive understanding of why, when you increase a minor principal stress, the von Mises stress (and the likelihood of failure) should go down?

So if S1 = 1000, S2 = 0 , then Svm = 1000.

If the S2 is now increased from 0 to 500. The von Mises stress will go from 1000 to 866

I understand this is how the equation works, but can someone give me an intuitive understanding of why, when you increase a minor principal stress, the von Mises stress (and the likelihood of failure) should go down?