- #1

Sam_A

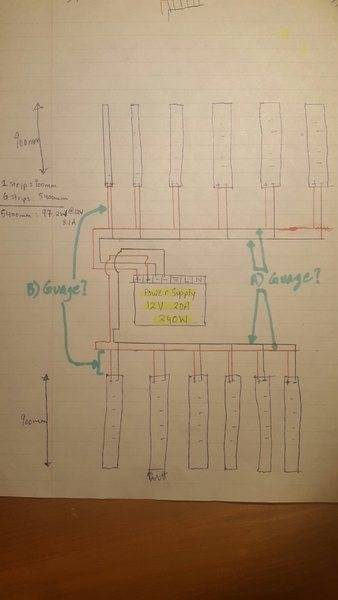

2 sets of 6x LED strips, each 12v 8.1a 97.2W, powered by a single cv 240W PSU, in parallel. The 2 sets are split at the PSU end, each set getting 120W separately. Schematic below,

What I don't know is what gauge wire to use at points A and B? Can you please explain what should be used and why?

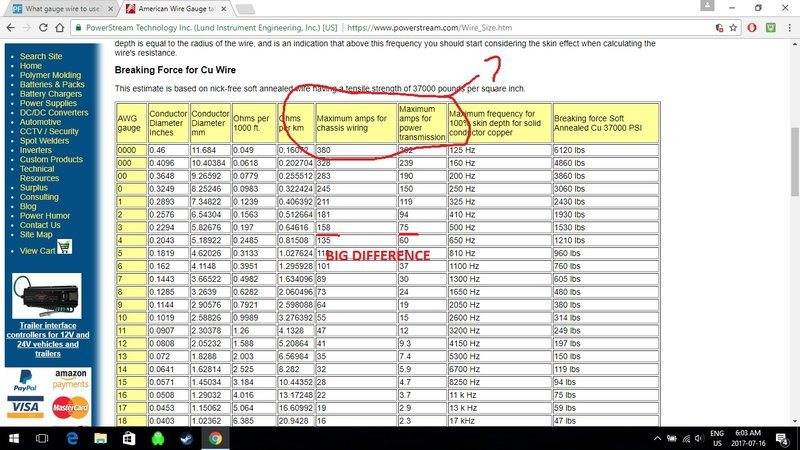

I looked at the AWG chart and I don't understand chassis wiring and power transmission wiring. What category do my wires fall under?

Also, I haven't figured out yet how long exactly will my wires be at point A and B. I know length of the wire has some effect on the gauges, but don't know what effect. Can anybody please present a general guideline or pattern describing what happens as I increase or decrease my wire length?

Much appreciated!

What I don't know is what gauge wire to use at points A and B? Can you please explain what should be used and why?

I looked at the AWG chart and I don't understand chassis wiring and power transmission wiring. What category do my wires fall under?

Also, I haven't figured out yet how long exactly will my wires be at point A and B. I know length of the wire has some effect on the gauges, but don't know what effect. Can anybody please present a general guideline or pattern describing what happens as I increase or decrease my wire length?

Much appreciated!

Last edited by a moderator: