- #1

Lith

Hi all,

My first physics question here - hope it's worthy and someone has some experience here :)

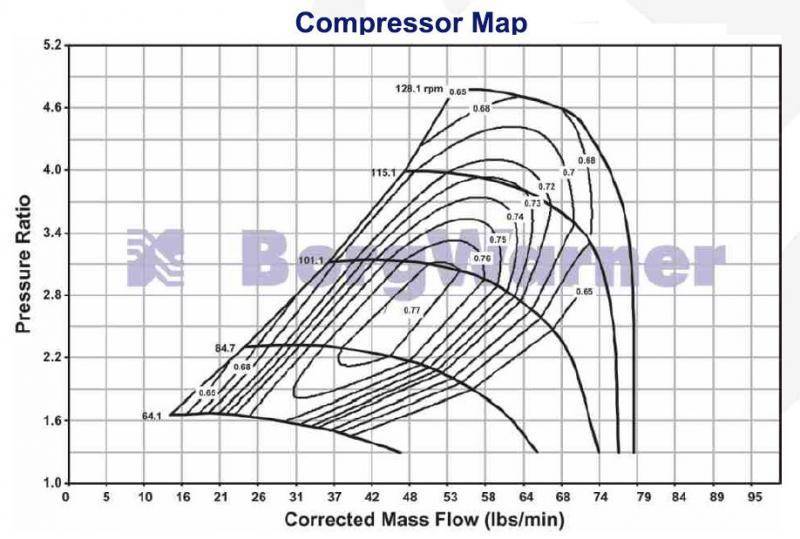

Hypothetically speaking, say you have an engine capable of swallowing 85lb/min of air at an absolute pressure of ~280kpa at sea level running a turbocharger running the compressor which the attached compressor map describes, and then try and run the setup at that pressure - assuming that there is still wastegating happening when the turbine speed reaches the 128100rpm stonewall point... what would you expect to happen next?

I have always pictured that so long is there is wasted exhaust energy at that point then the boost control system will be able to shut the gate and increase turbo rpm in an effort to increase flow, which will fail as the inlet air velocity will already be sonic - so turbo rpm will be forced to rapidly increase in vain until there is no longer sufficient exhaust flow through the turbine to further gain turbo rpm and everything will level off.

Does this sound plausible, or are there any other explanations people may have? Any input would be appreciated!

Cheers :)

My first physics question here - hope it's worthy and someone has some experience here :)

Hypothetically speaking, say you have an engine capable of swallowing 85lb/min of air at an absolute pressure of ~280kpa at sea level running a turbocharger running the compressor which the attached compressor map describes, and then try and run the setup at that pressure - assuming that there is still wastegating happening when the turbine speed reaches the 128100rpm stonewall point... what would you expect to happen next?

I have always pictured that so long is there is wasted exhaust energy at that point then the boost control system will be able to shut the gate and increase turbo rpm in an effort to increase flow, which will fail as the inlet air velocity will already be sonic - so turbo rpm will be forced to rapidly increase in vain until there is no longer sufficient exhaust flow through the turbine to further gain turbo rpm and everything will level off.

Does this sound plausible, or are there any other explanations people may have? Any input would be appreciated!

Cheers :)