- #1

Al_Pa_Cone

- 143

- 0

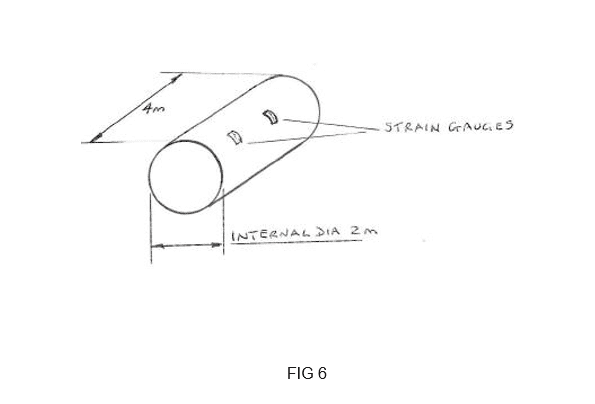

Q6. A cylindrical vessel 2m internal diameter and 4m long has a wall thickness of 6mm. Strain gauges are installed on the vessel to measure hoop strain (see FIG 6).

The Young's Modulus of the Material = 290 GN m^-2

The Yield Stress of the Material = 500 MPa

The Questions are

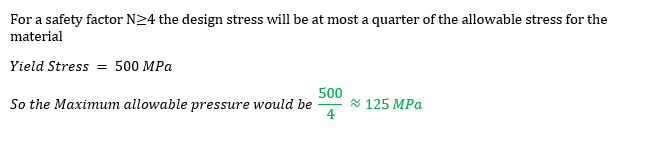

(i) What is the maximum allowable pressure if a factor of safety of 4 is to be used?

(ii) What pressure would a strain of 40με indicate?

For (i) I get:

Does this look correct?

for part 2, I cannot find the relevant equation to suit the pressure vessel. I have the hoop equation as

σ = pr/t

Where:

p = Pressure

r = radius of the vessel at 1000mm

t = Thickness of the vessel at 6mm

I am aware the strain is represented as a change in length by 0.000040 but I am not sure how to use this in my working out, given the fact I haven't used the Young's modulus of 290 GN m^-2 either.

Can anyone help me with this question?

The Young's Modulus of the Material = 290 GN m^-2

The Yield Stress of the Material = 500 MPa

The Questions are

(i) What is the maximum allowable pressure if a factor of safety of 4 is to be used?

(ii) What pressure would a strain of 40με indicate?

For (i) I get:

Does this look correct?

for part 2, I cannot find the relevant equation to suit the pressure vessel. I have the hoop equation as

σ = pr/t

Where:

p = Pressure

r = radius of the vessel at 1000mm

t = Thickness of the vessel at 6mm

I am aware the strain is represented as a change in length by 0.000040 but I am not sure how to use this in my working out, given the fact I haven't used the Young's modulus of 290 GN m^-2 either.

Can anyone help me with this question?