- #1

dsire4u

- 2

- 0

Hello,

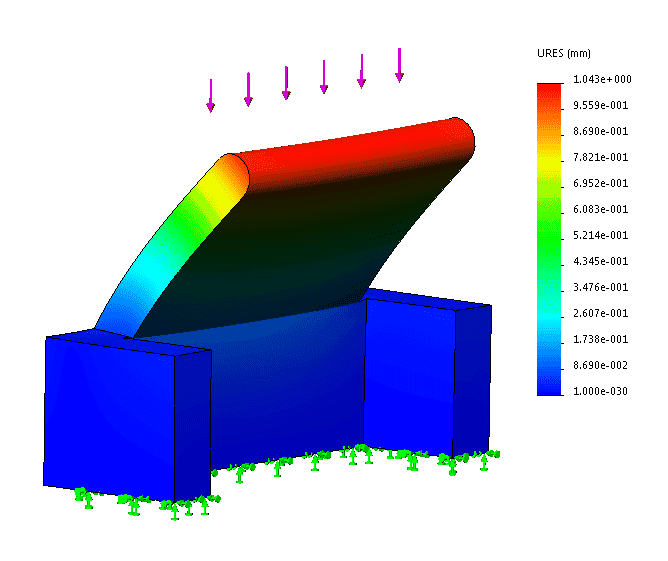

I have this model that required to be pressed vertically 1mm.

I successfully displaced 1mm vertically with 30N of force.

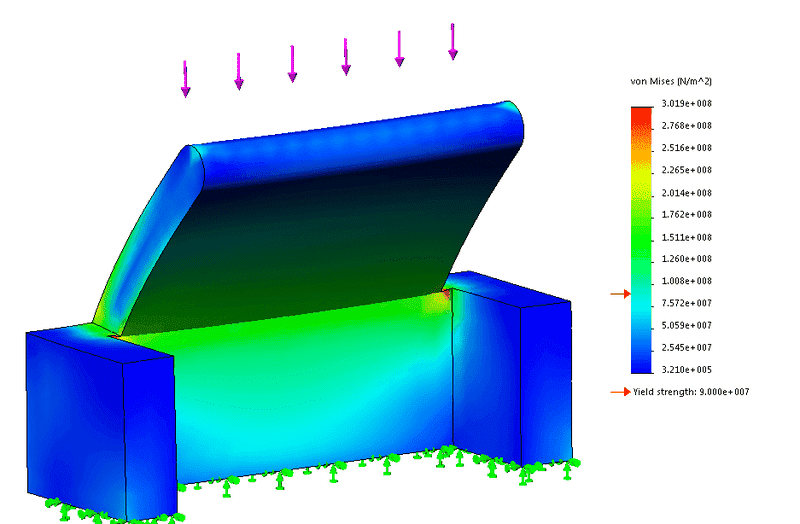

Unluckily, Von mises stress goes way beyond the yield strength.

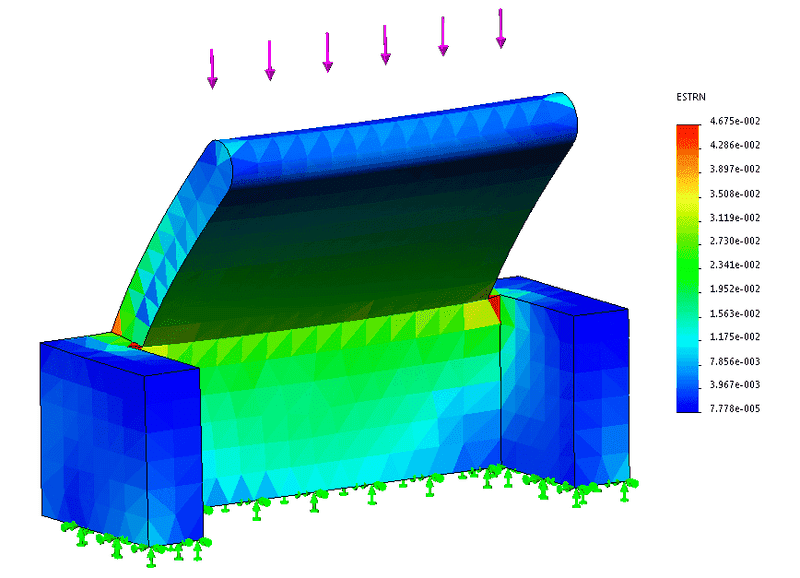

However, the strain is below the yield strain of 5%.

I do not understand how ductile/flexible material like Nylon will plastic deform with 30N of force applied.

Can someone explain to me if my model will plastic deform or not?

Please help,

Thank you

Included the x_b file of the part model.

I have this model that required to be pressed vertically 1mm.

I successfully displaced 1mm vertically with 30N of force.

Unluckily, Von mises stress goes way beyond the yield strength.

However, the strain is below the yield strain of 5%.

I do not understand how ductile/flexible material like Nylon will plastic deform with 30N of force applied.

Can someone explain to me if my model will plastic deform or not?

Please help,

Thank you

Included the x_b file of the part model.

Attachments

Last edited: