Hassan300

- 1

- 0

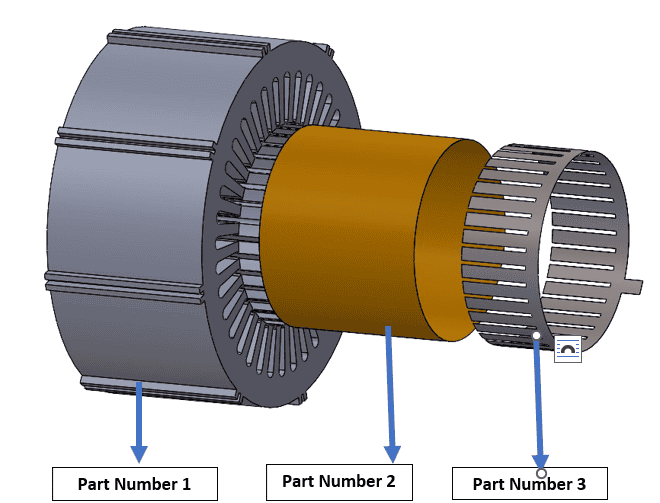

I am working on an electrical engineering project. However, I have come across a specific mechanical engineering problem. I have attached an image to describe what I want to do. I have primarily a stator core (made out of electrical steel laminated sheets) named part number "1". I have a double-sided adhesive insulation tape named part number "2". Lastly, I have a sheet of electrical steel, which I call a plate, named part number "3". The part number 2 will be put on the inner diameter of part number 1. After that, part number 3 will be put on the inner diameter of part number 1, which already has the part number 2. The part number 3 is made up of multiple strips (as you can see in the figure). Can you guys tell me the most efficient and precise way of putting these parts together, like I described above? You are welcome to give the suggestions regarding techniques or the tools. You are welcome to ask any follow-up questions.

Last edited by a moderator: