- #1

DadoNoah

- 6

- 0

- TL;DR Summary

- Trying to derive an equation for the force applied to a syringe plunger as a function of desired flow rate, fluid viscosity, and syringe geometry. Am I using the Poiseuille equation correctly?

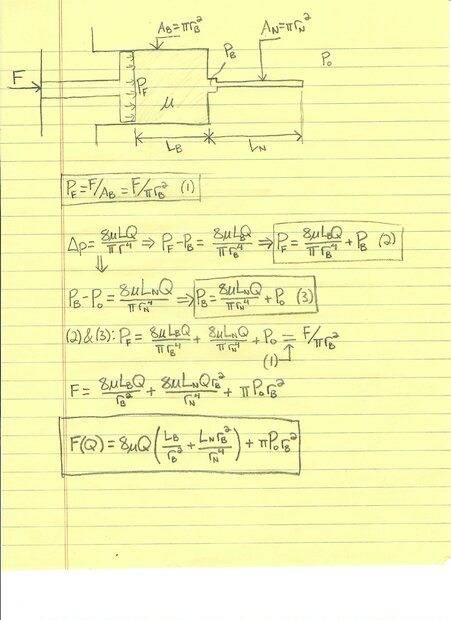

I'm currently working on a precise glue/resin dispenser, and I'm trying to derive an equation for the force one must exert on a syringe plunger as a function of the desired flow rate Q, and also accounting for the fluid viscosity and the syringe barrel and needle geometry. I've attached a scan of my calculations using the Poiseuille equation, but it's been quite a while since I've used it, so I've got no idea if I'm doing it correctly. Are you even allowed to daisy-chain the two pipe sections together like I have? If someone could take a look and tell me if I'm on the right track, I'd really appreciate it!

If you're having trouble with my handwriting, the final equation I came up with is:

F(Q) = 8μQ ( LB/rB2 + LNrB2/rN4 ) + πP0rB2

If you're having trouble with my handwriting, the final equation I came up with is:

F(Q) = 8μQ ( LB/rB2 + LNrB2/rN4 ) + πP0rB2