- #1

Wetmelon

- 154

- 1

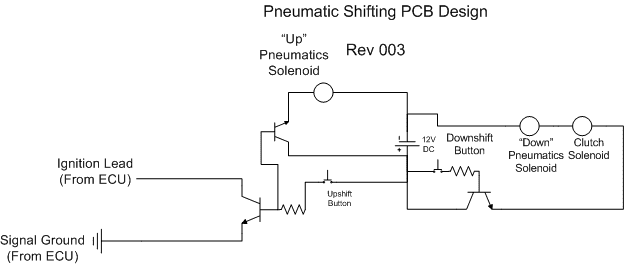

Hey again. I have a circuit that I've made and I was told I should put resistors in so that I don't blow out my transistors and buttons. Ok, I can do that... but I have no idea what size of resistor I need! Picture:

I'm using TIP41C Transistors:

http://www.drixsemi.com/TIP41C.PDF

I think what I needed from this sheet was the "Continuous base current" of 3A?

12V = 3A * R

R = 4ohm?

Does that sound right? Am I oversimplifying it?

I'm using TIP41C Transistors:

http://www.drixsemi.com/TIP41C.PDF

I think what I needed from this sheet was the "Continuous base current" of 3A?

12V = 3A * R

R = 4ohm?

Does that sound right? Am I oversimplifying it?