Paavo Palikka

- 10

- 0

Hello,

I have been thinking about following problem: I have some kind of piston and cylinder with oil. I know the pressure in oil. Let's say it is 500bar. I would want to know how much is displacement of piston.

Let's say bulk modulus of oil is 3Gpa.

Let's also say that bulk modulus of materials in piston and cylinder is 50Gpa.

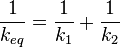

How should I get the total bulk modulus of the system? It somehow seems that I can't just calculate it followingly:

...

...

Should I somehow take volumes into account? What is right equation?

-Paavo Palikka

I have been thinking about following problem: I have some kind of piston and cylinder with oil. I know the pressure in oil. Let's say it is 500bar. I would want to know how much is displacement of piston.

Let's say bulk modulus of oil is 3Gpa.

Let's also say that bulk modulus of materials in piston and cylinder is 50Gpa.

How should I get the total bulk modulus of the system? It somehow seems that I can't just calculate it followingly:

Should I somehow take volumes into account? What is right equation?

-Paavo Palikka