Nadia

- 4

- 2

- TL;DR

- Exercise about estimating the life of a rod given a graph and an equation to work with. (Ex. 3.6 from Inelastic Deformation of Metals: Models, Mechanical Properties, and Metallurgy from D. C. Stouffer and L. Thomas Dame)

I'm sorry I'm uploading lots of images because I don't know how to write equations here.

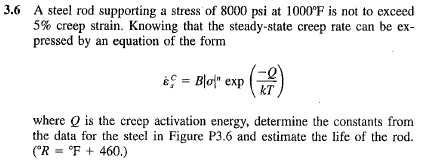

PROBLEM DESCRIPTION

I have to solve this problem:

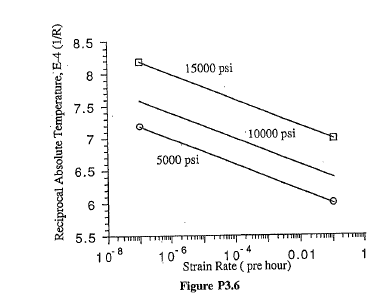

Figure P3.6:

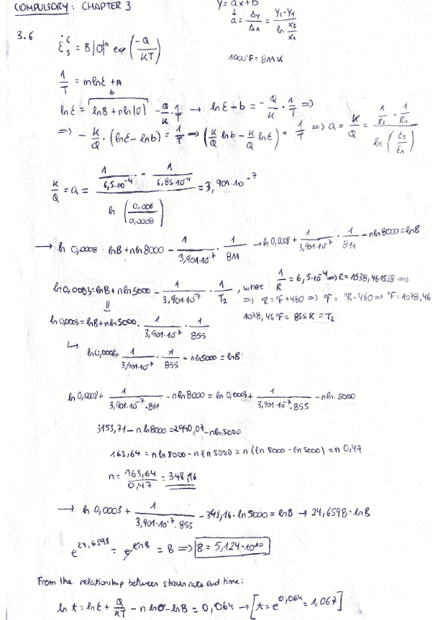

MY SOLUTION

I did this:

THE CORRECTION

I got this as a correction:

- Don't use the middle line in figure P3.6 in my calculations.

- Start finding Q/k but for the top and bottom line, if they are not identical, deal with it.

- You will now have the temperature dependance.

- Plot ln(eps-dot)+Q/kT as a function of ln(Sigma)

- You get two points from which you can calculate n and B

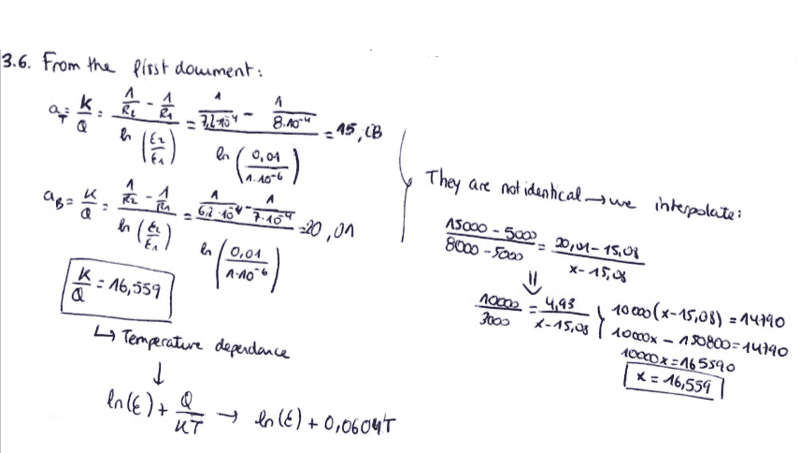

SOLUTION AFTER THE CORRECTION

I've now done this part but I think it's wrong and I also don't know how to keep going with the plot.

PROBLEM DESCRIPTION

I have to solve this problem:

Figure P3.6:

MY SOLUTION

I did this:

THE CORRECTION

I got this as a correction:

- Don't use the middle line in figure P3.6 in my calculations.

- Start finding Q/k but for the top and bottom line, if they are not identical, deal with it.

- You will now have the temperature dependance.

- Plot ln(eps-dot)+Q/kT as a function of ln(Sigma)

- You get two points from which you can calculate n and B

SOLUTION AFTER THE CORRECTION

I've now done this part but I think it's wrong and I also don't know how to keep going with the plot.

Last edited: