- #1

jonhswon

- 10

- 4

- TL;DR Summary

- To me it seems linda cycle can not liquidize nitrogen.

Please explain me, can it liquidize N2? Here is how I come to this result:

Hi !

To me it seems linda cycle can not liquidize nitrogen.

Please explain me, can it liquidize N2? Here is how I come to this result:

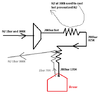

Imagine compressor take nitrogen 1bar 300k and gives 200bar hot, but cooled to 200bar 315k.

Next n2 is cooled in counterflow heat exchanges (hex) by cool n2 that wasnt liquidized in next step.

I am assuming that heat exchangers are not ideal, but say ~95% efficient, slightly worse than ideal.

Then n2 is passed from throttling valve becomes 1bar and colder, hopefully cold enough that some liquid is produced.

So now to some steady state calculation:

I start by assuming temperature at which n2 leaves hex is 170K, this is highest that can yield any liquid droplets at all.

https://upload.wikimedia.org/wikipedia/commons/9/9d/Throttling_in_Ts_diagram_01.jpg

Look at this T-s diagram of n2.

Expanding n2 from 200bar 170k to 1bar 78k, say maybe 0.01%liquid (this isnt anything at all) and 99.99% gas.

Now back to check if hex works as expected.

For hex, heat lost = heat gained.

Heat gained by cold n2 = Cp*dT = 1.05*(300-78) = 233

Heat lost by hot n2 = Cp*dT = 1.6*dT

(Cp values obatained from nist website, and vary depending on pressure and temperature)

233=1.6*dT

dT=145

gas exiting hex is 315-145=170K, correct! If this was otherwise then I guessed wrong, but lucky.

Final words:

So you see, even using 200bar compressor we are barely getting any liquid at all, close to none.

And increasing pressure doesn't make things better, maybe only tiny bit better. Check t-s diagram.

Do I have a mistake.

Or is linda-hampsons so impractical ?

edit: this can be moved to thermodynamics maybe. [Done.]

To me it seems linda cycle can not liquidize nitrogen.

Please explain me, can it liquidize N2? Here is how I come to this result:

Imagine compressor take nitrogen 1bar 300k and gives 200bar hot, but cooled to 200bar 315k.

Next n2 is cooled in counterflow heat exchanges (hex) by cool n2 that wasnt liquidized in next step.

I am assuming that heat exchangers are not ideal, but say ~95% efficient, slightly worse than ideal.

Then n2 is passed from throttling valve becomes 1bar and colder, hopefully cold enough that some liquid is produced.

So now to some steady state calculation:

I start by assuming temperature at which n2 leaves hex is 170K, this is highest that can yield any liquid droplets at all.

https://upload.wikimedia.org/wikipedia/commons/9/9d/Throttling_in_Ts_diagram_01.jpg

Look at this T-s diagram of n2.

Expanding n2 from 200bar 170k to 1bar 78k, say maybe 0.01%liquid (this isnt anything at all) and 99.99% gas.

Now back to check if hex works as expected.

For hex, heat lost = heat gained.

Heat gained by cold n2 = Cp*dT = 1.05*(300-78) = 233

Heat lost by hot n2 = Cp*dT = 1.6*dT

(Cp values obatained from nist website, and vary depending on pressure and temperature)

233=1.6*dT

dT=145

gas exiting hex is 315-145=170K, correct! If this was otherwise then I guessed wrong, but lucky.

Final words:

So you see, even using 200bar compressor we are barely getting any liquid at all, close to none.

And increasing pressure doesn't make things better, maybe only tiny bit better. Check t-s diagram.

Do I have a mistake.

Or is linda-hampsons so impractical ?

edit: this can be moved to thermodynamics maybe. [Done.]

Last edited by a moderator: