belae1ka

- 13

- 0

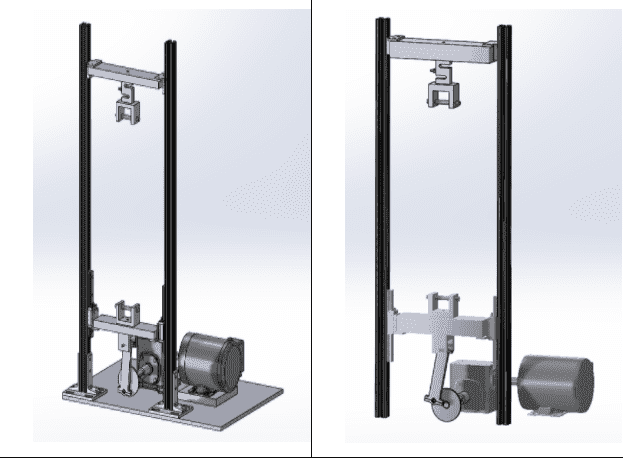

The project I am working on is to design the control system for a shock dynamometer. I am using Labview and communicating to the VFD using Modbus. The shock dyno will look a little something like this;

So one of the main objectives in my project is to produce a plot as seen below;

The force will be data coming from a load cell.

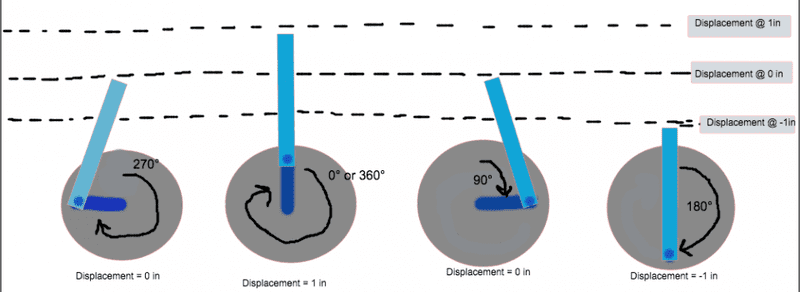

The Displacement will be the linear displacement of the shock being tested (the compression/rebound). To clarify what I mean, I have included the figure below;

My question is: Do you think I would be able to acquire the shaft position from my motor using my VFD?

My question is: Do you think I would be able to acquire the shaft position from my motor using my VFD?

I called AutomationDirect (the manufacturer of the VFD) and asked them this question and they told me no considering the motor I am using (3 phase) is not a servo motor but I just wanted to double check with the forums to make sure. I tried reading the encoder feedback registers through Modbus and moving the shaft by hand to see if any values changed but no luck. I'm guessing I may have to implement some kind of proximity sensor in order to acquire the data for displacement. Due to the design of the dyno, I don't think I would be able to attach an external rotary encoder to the shaft of the motor. Any suggestions?

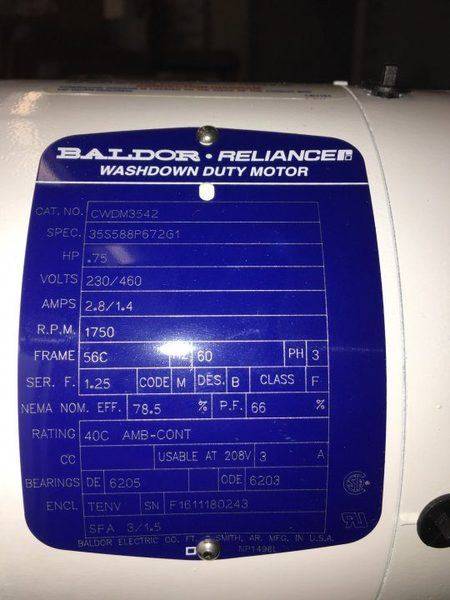

In case it helps, below is a picture of the nameplate on the motor and also the link and model of the VFD I am using.

VFD: DURApulse GS3-21P0 AC Drive

VFD Manual: https://cdn.automationdirect.com/sta.../gs3m/gs3m.pdf

Thank you.

-Kevin

So one of the main objectives in my project is to produce a plot as seen below;

The force will be data coming from a load cell.

The Displacement will be the linear displacement of the shock being tested (the compression/rebound). To clarify what I mean, I have included the figure below;

I called AutomationDirect (the manufacturer of the VFD) and asked them this question and they told me no considering the motor I am using (3 phase) is not a servo motor but I just wanted to double check with the forums to make sure. I tried reading the encoder feedback registers through Modbus and moving the shaft by hand to see if any values changed but no luck. I'm guessing I may have to implement some kind of proximity sensor in order to acquire the data for displacement. Due to the design of the dyno, I don't think I would be able to attach an external rotary encoder to the shaft of the motor. Any suggestions?

In case it helps, below is a picture of the nameplate on the motor and also the link and model of the VFD I am using.

VFD: DURApulse GS3-21P0 AC Drive

VFD Manual: https://cdn.automationdirect.com/sta.../gs3m/gs3m.pdf

Thank you.

-Kevin