- #1

Stormer

- 113

- 22

- TL;DR Summary

- Will a centrifugal clutch work in the reverse direction, or will it loose almost all of the torque as compared to when it is driven in the correct direction?

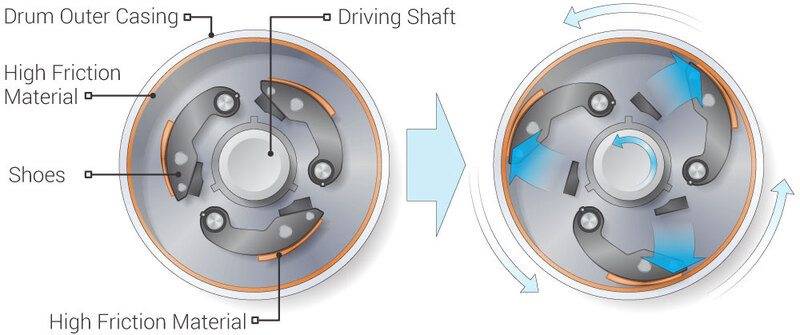

As seen by the image below a centrifugal clutch has a pin/hinge in one end of each shoe arm and dependent on the angle of the shoe arm in the fully extended position that will create a wedging action to further increase the friction against the drum beyond the centrifugal force alone. Kind of like the wedging action of the sprags in a sprag clutch. And this wedging action will not happen if it rotates in the other direction, then you will only have the centrifugal force pushing out and creating the friction against the drum. But how much of the friction is caused by the centrifugal force compared to the wedging action? Will this kind of clutch almost not work at all if it is driven in the reverse direction?