CarlLyon09

- 2

- 0

Hi,

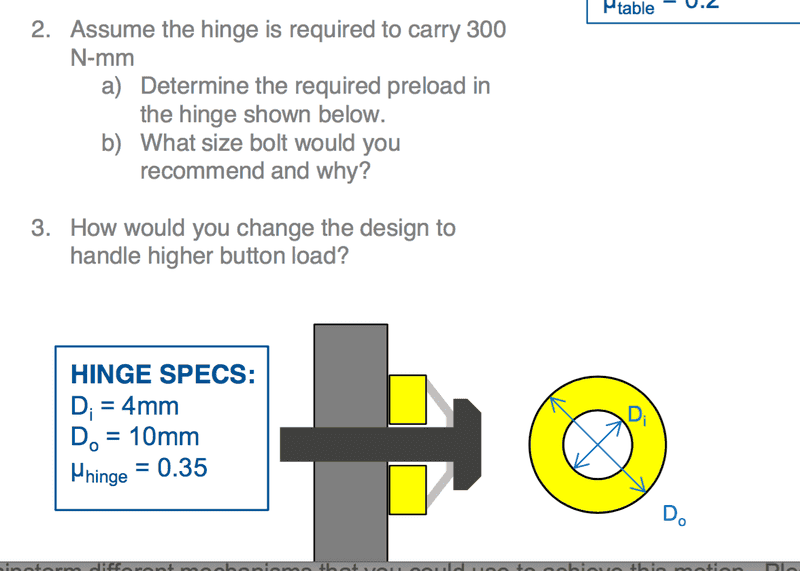

I'm looking at a friction hinge design problem. See the image below for details. Looking through a machinist's handbook (pg. 1495), I get a few equations for fastener preload and wrench torque.

T = k * Fi * d, where T is wrench torque, Fi is preload, and d is the nominal bolt diameter, and k is a friction constant

Fi = 0.75 * At * Sp, where At is the bolt tensile area, and Sp is the proof strength of the bolt

By definition, Sp = 0.85*Sy, where Sy is the yield strength of the bolt.

To calculate preload, I used Sy = 340 MPa for Class 4.8 low/medium carbon steel bolts.

For At, I wasn't so sure what to use in this case. I assumed it was the area of the yellow looking washer.

Calculating preload, I ended up getting Fi = 14,300 N, which seems like a lot...

Fi = 0.75 * pi/4 * (0.01 m - .004 m)^2 * 0.85 * 340 x 10^6 Pa

Using that value, I calculated the nominal bolt diameter, d, using the first equation and got d = 0.06mm which doesn't seem to be right...

d = 300 N*mm / (0.35 * Fi)

I feel like the solution should be pretty simple... am I overcomplicating things?

I'm looking at a friction hinge design problem. See the image below for details. Looking through a machinist's handbook (pg. 1495), I get a few equations for fastener preload and wrench torque.

T = k * Fi * d, where T is wrench torque, Fi is preload, and d is the nominal bolt diameter, and k is a friction constant

Fi = 0.75 * At * Sp, where At is the bolt tensile area, and Sp is the proof strength of the bolt

By definition, Sp = 0.85*Sy, where Sy is the yield strength of the bolt.

To calculate preload, I used Sy = 340 MPa for Class 4.8 low/medium carbon steel bolts.

For At, I wasn't so sure what to use in this case. I assumed it was the area of the yellow looking washer.

Calculating preload, I ended up getting Fi = 14,300 N, which seems like a lot...

Fi = 0.75 * pi/4 * (0.01 m - .004 m)^2 * 0.85 * 340 x 10^6 Pa

Using that value, I calculated the nominal bolt diameter, d, using the first equation and got d = 0.06mm which doesn't seem to be right...

d = 300 N*mm / (0.35 * Fi)

I feel like the solution should be pretty simple... am I overcomplicating things?

Last edited: