Discussion Overview

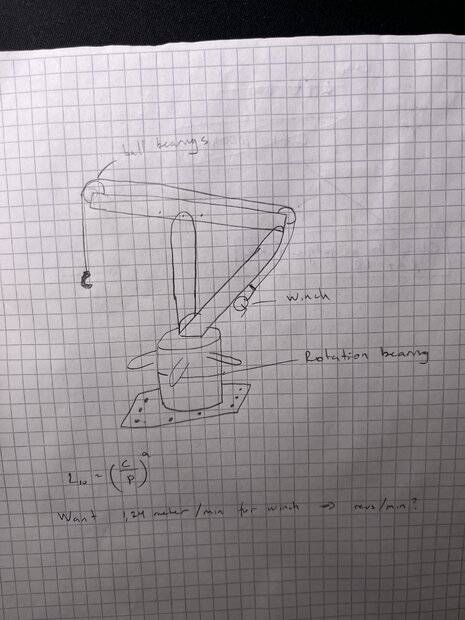

The discussion revolves around determining the appropriate bearings for a manual crane capable of lifting a maximum weight of 1000 kg and pulling a winch cable at a specified rate. Participants explore the forces involved, including radial and axial loads, and the calculations necessary to ensure the crane's structural integrity and functionality.

Discussion Character

- Technical explanation

- Mathematical reasoning

- Debate/contested

Main Points Raised

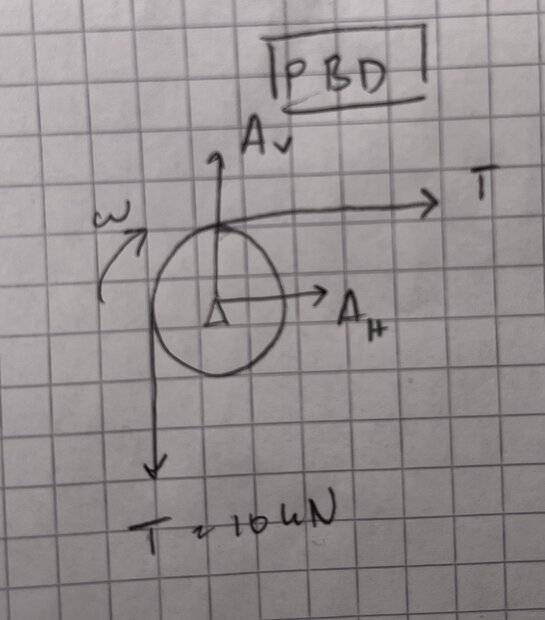

- One participant estimates the radial force P to be 10 kN based on the weight and winch specifications, but seeks validation for this assumption.

- Another participant suggests that the base of the lifting arms should be a thick wall steel tube and discusses the side thrust forces involved.

- There is a discussion about determining reaction forces A_H and A_V, with references to Newton's Second Law and the relationship between linear and angular velocities.

- Participants express uncertainty about how to determine the radius for the pulley and its impact on the forces involved.

- One participant questions the presence of axial loads and discusses the potential for axial forces in the context of the crane's design.

- Another participant mentions that the radial force on the bearing could vary based on the tension in the winch wire and the angle of the pulley.

- There are calculations presented for dynamic load capacity based on assumed lifetimes and bearing ratings, with some participants questioning the validity of these calculations.

- Discussion includes the need for a clearer diagram of the crane's components to facilitate better understanding and analysis.

Areas of Agreement / Disagreement

Participants express varying levels of agreement on the calculations and assumptions regarding forces, with some proposing different values for axial loads and radial forces. The discussion remains unresolved regarding the exact forces acting on the crane and the appropriate bearing specifications.

Contextual Notes

Participants note that the calculations depend on various assumptions, including the definitions of forces and the geometry of the crane. There is also mention of the need for more detailed diagrams to clarify the mechanical setup.

Who May Find This Useful

Individuals interested in mechanical engineering, crane design, or bearing selection may find this discussion relevant, particularly those looking to understand the forces involved in lifting mechanisms.