- #1

phy_optics

- 12

- 0

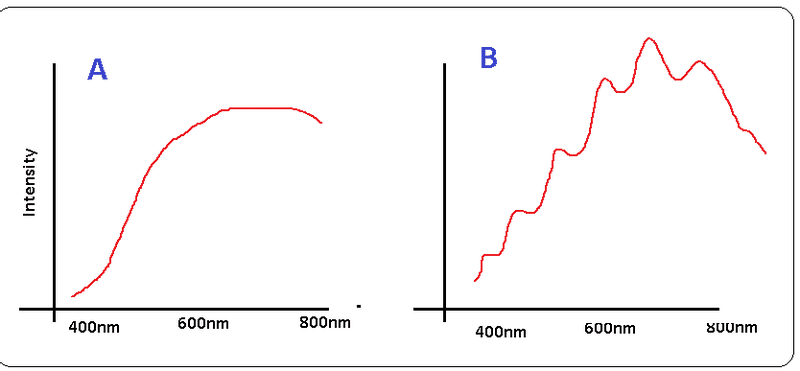

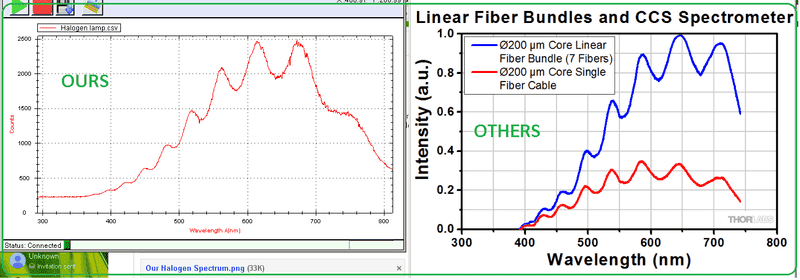

12V, 50W, MR16 halogen lamp spectrum is measured as shown ('B') with our newly developed mini-spectrometer having resolution ~1nm. But in internet it was similar to 'A' (We don't know how much resolution spectrometer they've used). Could anybody let me know what exactly the spectrum look like when measured with ~1nm resolution spectrometer (A or B) and why?

just check the below link for more understanding

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_ID=3482

just check the below link for more understanding

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_ID=3482