Gingerbunny82

- 13

- 0

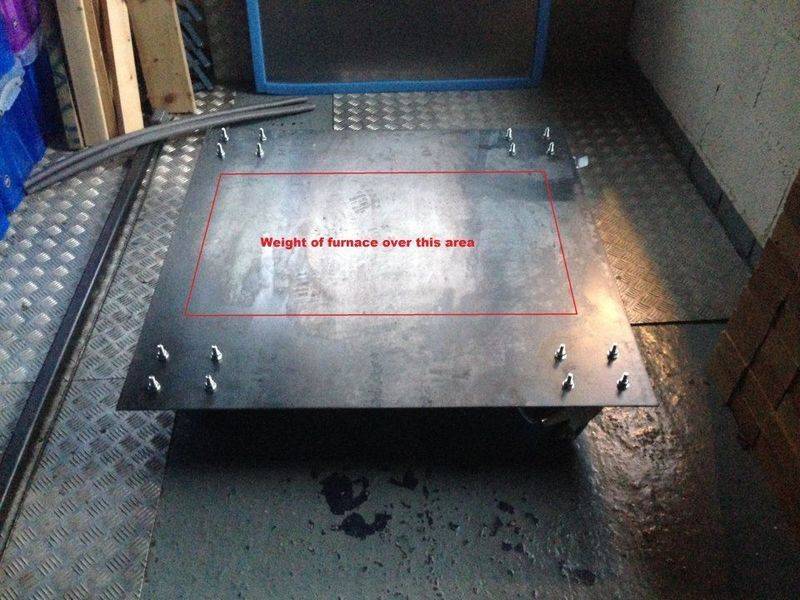

Hey folks, I'm building this steel platform to support a furnace, the furnace will weigh about 350kg and cover approximately the area shown below:

The platform itself is mild steel sheet, 100cm x 100cm x 4mm thick.

Each castor is rated for 300kg each.

The problem I'm having is that even with the weight of one person ~ 80kg the steel plate is bending in the middle. Now I expected this would happen so I tried to brace the bottom of the plate with square tubing.

The square tubing is 40mm x 40mm and 4mm wall thickness.

I added two 1m length braces spanning the full length of the plate, what I was wondering is if I add a brace running across (perpendicular) to the current braces will that help prevent the plate bending in the middle. Or is the plate just too thin to support the weight of the furnace?

Below is a picture showing the plate bending with just around 40kg weight in the middle:

I'm willing to go back to the drawing board if necessary, ideally I would be looking at less than 5mm bend in the middle. Thanks in advance for the help :)

The platform itself is mild steel sheet, 100cm x 100cm x 4mm thick.

Each castor is rated for 300kg each.

The problem I'm having is that even with the weight of one person ~ 80kg the steel plate is bending in the middle. Now I expected this would happen so I tried to brace the bottom of the plate with square tubing.

The square tubing is 40mm x 40mm and 4mm wall thickness.

I added two 1m length braces spanning the full length of the plate, what I was wondering is if I add a brace running across (perpendicular) to the current braces will that help prevent the plate bending in the middle. Or is the plate just too thin to support the weight of the furnace?

Below is a picture showing the plate bending with just around 40kg weight in the middle:

I'm willing to go back to the drawing board if necessary, ideally I would be looking at less than 5mm bend in the middle. Thanks in advance for the help :)