Discussion Overview

The discussion revolves around troubleshooting a failed electronic amplifier project, focusing on issues such as excessive hum, microphonic components, and interaction between gain and volume controls. Participants explore potential causes and solutions, sharing insights on design complexities and troubleshooting strategies.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Troubleshooting

Main Points Raised

- Some participants suggest that the 60Hz hum could indicate an open input, wire routing issues, or a ground loop, while others propose it might be related to the power supply, expecting a 120Hz hum instead.

- There is a consensus among several participants that addressing the hum issue first is advisable, as it may influence other problems.

- Participants discuss the possibility that the microphonic condition could stem from high gain, faulty tubes, corroded sockets, or poor solder joints.

- One participant mentions that the hum decreases as preamp tubes are removed, indicating that the issue may be present in all preamp stages.

- Another participant suggests using a 6-volt battery to power the preamp heaters to potentially reduce hum.

- There are mentions of specific components and configurations, such as the RCA 7199 tube and the use of preamp heaters as output stage cathode resistors, as potential solutions to the hum issue.

- One participant reports that the major hum issue was resolved after repairing an incorrectly wired bias circuit, but the channel one circuit remains distorted.

- Participants express uncertainty about whether the design will ultimately work properly, indicating a need for further testing and adjustments.

Areas of Agreement / Disagreement

Participants generally agree on the need to address the hum issue first, but there are multiple competing views regarding the underlying causes and solutions for the various problems encountered. The discussion remains unresolved, with ongoing troubleshooting and exploration of different approaches.

Contextual Notes

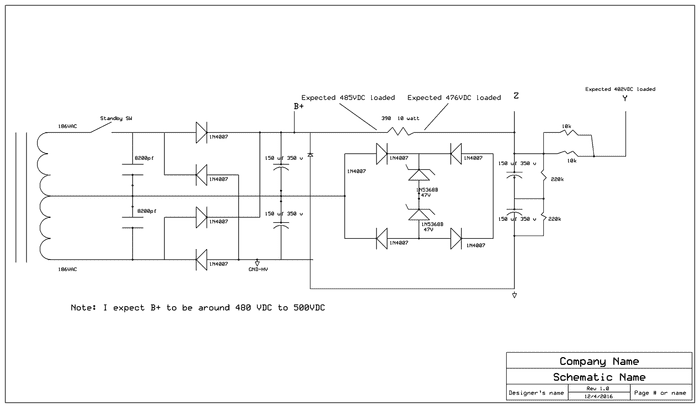

Participants mention the complexity of the amplifier design and the potential for errors in wiring and component connections. There is also a reference to the need for clearer schematics and the importance of verifying connections and solder joints.

Who May Find This Useful

Individuals interested in electronics troubleshooting, amplifier design, and those facing similar issues with electronic projects may find this discussion beneficial.