BuddyBoy

- 41

- 2

- Homework Statement

- Calculate the ampacity of a nickel strip with thickness of 0.10 mm, width of 10 mm, and length 50 mm, assuming a DC current.

- Relevant Equations

- See below. There are many.

I'm not sure what forum to put this in. Sorry if I have placed this in the wrong forum. This topic seems to require understanding of both electrical and mechanical, so I'm placing this in the physics forum. Knowledge of this subject doesn't appear to be too common, so I'm not posting it in the introductory forum.

This is a theoretical thought exercise ONLY to help in understanding the ideas and concepts. The numbers in the question statement are MADE UP, simple numbers to do math with.

I'm hoping to understand how ampacity of a conductor is calculated and I have some questions. There are ampacity tables you can look up online, but what do you do when you are using a conductor that is not in these tables, and where do these numbers even come from? Are these numbers really just experimental data determined from testing, or can they be obtained with math? I'm attempting to understand where these numbers come from by attempting to calculate such a value in this theoretical thought exercise.

Ampacity is the current a conductor can handle before it is considered "overheated".

Question Statement: Calculate the ampacity of a nickel strip with thickness of 0.10 mm, width of 10 mm, and length 50 mm, assuming a DC current application.

Insert Equation 2 into Equation 1to get Equation 3.

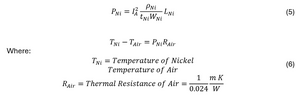

Insert Equation 3 into Equation 4 to get Equation 5.

Insert Equation 5 into Equation 6 to get Equation 7.

Rearrange Equation 7 for ampacity current to get Equation 8.

Inserting the values of constants, results in Equation 9.

Looking online, ampacity does not care about the length of material. This would explain why the units do not work out. I now have based on the previous equations, Equation 10-14 taking this into consideration.

Inserting the values for the constants results in Equation 15.

Assuming that I have done everything above correctly, I have the following questions still:

Thank you for any help in understanding this!

This is a theoretical thought exercise ONLY to help in understanding the ideas and concepts. The numbers in the question statement are MADE UP, simple numbers to do math with.

I'm hoping to understand how ampacity of a conductor is calculated and I have some questions. There are ampacity tables you can look up online, but what do you do when you are using a conductor that is not in these tables, and where do these numbers even come from? Are these numbers really just experimental data determined from testing, or can they be obtained with math? I'm attempting to understand where these numbers come from by attempting to calculate such a value in this theoretical thought exercise.

Ampacity is the current a conductor can handle before it is considered "overheated".

Question Statement: Calculate the ampacity of a nickel strip with thickness of 0.10 mm, width of 10 mm, and length 50 mm, assuming a DC current application.

Insert Equation 2 into Equation 1to get Equation 3.

Insert Equation 3 into Equation 4 to get Equation 5.

Insert Equation 5 into Equation 6 to get Equation 7.

Rearrange Equation 7 for ampacity current to get Equation 8.

Inserting the values of constants, results in Equation 9.

Looking online, ampacity does not care about the length of material. This would explain why the units do not work out. I now have based on the previous equations, Equation 10-14 taking this into consideration.

Inserting the values for the constants results in Equation 15.

Assuming that I have done everything above correctly, I have the following questions still:

- The ampacity does not care about length of the conductor, but why? I'm really not understanding this. I would assume the longer the conductor, the more current it can handle without overheating.

- What temperature should I use for the acceptable temperature in Kelvin for Nickel before it is considered "overheated"?

- What temperature should I use for ambient air in Kelvin?

Attachments

Last edited: