Discussion Overview

The discussion revolves around methods for cutting a board to achieve a spherical bend, particularly in the context of bathroom remodeling using materials like polystyrene (XPS) board. Participants explore various cutting techniques, patterns, and the feasibility of achieving a spherical shape through different approaches.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Conceptual clarification

Main Points Raised

- Some participants suggest cutting a triangular patterned serration, akin to a geodesic dome, to facilitate bending.

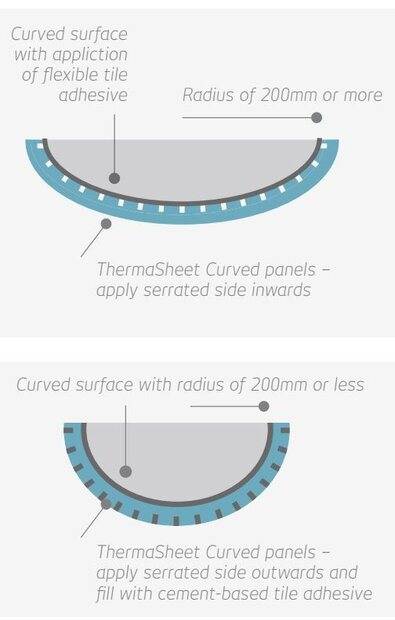

- Others propose that V-shaped slots cut on both sides of the sheet may allow for the necessary compression to approximate a spherical surface.

- A participant questions the strength of the vertices when multiple cuts intersect, indicating a need for practical testing.

- One viewpoint argues that achieving a spherical bend is impossible without cutting wedges and stitching them together, similar to a soccer ball's construction.

- Another participant mentions that compression in one direction can be achieved with wood through steaming, but spherical bending requires multi-directional bending, which wood cannot accommodate.

- Some contributions reference the map projection problem, drawing parallels to the challenges of creating a spherical surface from a flat one.

- There are suggestions to consider alternative methods, such as 3D printing or using existing spherical objects as molds.

- One participant emphasizes the importance of understanding the application requirements, such as the radius and stresses involved in the desired shape.

- Another proposes using plaster to smooth out the surface after achieving an approximation of the sphere through cutting and bending techniques.

- Discussions also touch on the historical context of geodesic structures and their relevance to the problem at hand.

Areas of Agreement / Disagreement

Participants express a range of views, with no consensus on a single method for achieving a spherical bend. Disagreements exist regarding the feasibility of various cutting techniques and the materials involved.

Contextual Notes

Some limitations include the dependence on material properties, the need for specific cutting patterns, and the unresolved nature of how to effectively compress and bend the material without compromising its integrity.