HomeExperiement

- 55

- 5

Hi!

I would like to know how to exactly calculate required wire diameter? For example, here I found this calculator on internet: https://www.solar-wind.co.uk/CST.html .

It takes acceptable loss, volts, amps, and cable length for arguments. It specifies Vdc. Would it be different formula with AC? In this case I am interested in DC.

This site uses the following code:

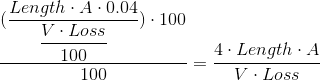

Which in formulas looks like this:

Which doesn't look too complex to understand, but can anyone explain what that 0.04 does?

I am interested to know, if it's correct calculator at all and if it is then what needs to be done in formulas to make it work with other materials? I assume this one works for copper. But if for example I want to make wire out of aluminium or gold or any other periodic table element that conducts electricity, how would that formula look like then?

I would like to know how to exactly calculate required wire diameter? For example, here I found this calculator on internet: https://www.solar-wind.co.uk/CST.html .

It takes acceptable loss, volts, amps, and cable length for arguments. It specifies Vdc. Would it be different formula with AC? In this case I am interested in DC.

This site uses the following code:

JavaScript:

Result = Math.round(((localobject.crun.value * localobject.amps.value * 0.04) / ((localobject.volts.value * localobject.perc_loss.value) / 100 )) * 100) / 100;Which in formulas looks like this:

Which doesn't look too complex to understand, but can anyone explain what that 0.04 does?

I am interested to know, if it's correct calculator at all and if it is then what needs to be done in formulas to make it work with other materials? I assume this one works for copper. But if for example I want to make wire out of aluminium or gold or any other periodic table element that conducts electricity, how would that formula look like then?