SUMMARY

This discussion focuses on coupling a 1/4" diameter rod of a small wind turbine to a motor axle measuring 2-3 millimeters. The recommended solution is to use a short piece of rubber tube, such as small engine fuel hose, to connect the two shafts flexibly. Various coupling options are available, including solid couplings, flexible couplings, and double loop couplings, with considerations for torque and alignment. For optimal performance, it is crucial to maintain the turbine blade's angle of attack and consider using a gearbox for better torque and RPM matching.

PREREQUISITES

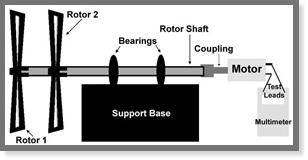

- Understanding of shaft coupling types (e.g., flexible, solid, double loop)

- Basic knowledge of torque and RPM relationships in motors

- Familiarity with small engine fuel hoses and their applications

- Awareness of the importance of maintaining blade angle of attack in wind turbines

NEXT STEPS

- Research "flexible shaft couplings" for small motors

- Learn about "gearbox torque matching" for wind turbine applications

- Explore "aerodynamic stall prevention" techniques for turbine blades

- Investigate "set screw coupling" designs and their effectiveness

USEFUL FOR

Engineers, hobbyists, and DIY enthusiasts involved in wind turbine design and construction, particularly those focusing on motor coupling and torque management.