artis

- 1,479

- 977

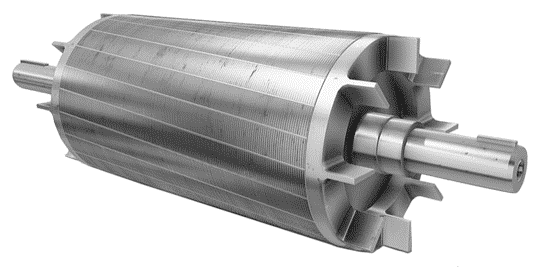

I had to repair (change bearings) on a single phase induction motor recently and I recalled an age old question I've had.

What are the rotor end ring blades made for ?

The only reasonable answer I can come up with is - they are for cooling of the stator winding ends that extend out of the stator?

And one additional question. I've seen on older style induction motors the rotor aluminum bars, that form single loop circuits in the rotor , not visible on the rotor surface , instead they are some mm or so embedded into the rotor and the surface is completely covered by the electrical steel lamination outer surface. On newer rotors I see the aluminum bars extend to the very surface like in the picture above.

Now I would think that the closer the rotor bars are to the stator magnetic field the more flux passes through them and stronger the induction and the motor more efficient for a given size, is that true?

I assume in the older designs they did not extend the aluminum bars to the surface due to machining and mechanical issues?

What are the rotor end ring blades made for ?

The only reasonable answer I can come up with is - they are for cooling of the stator winding ends that extend out of the stator?

And one additional question. I've seen on older style induction motors the rotor aluminum bars, that form single loop circuits in the rotor , not visible on the rotor surface , instead they are some mm or so embedded into the rotor and the surface is completely covered by the electrical steel lamination outer surface. On newer rotors I see the aluminum bars extend to the very surface like in the picture above.

Now I would think that the closer the rotor bars are to the stator magnetic field the more flux passes through them and stronger the induction and the motor more efficient for a given size, is that true?

I assume in the older designs they did not extend the aluminum bars to the surface due to machining and mechanical issues?