kaadeeka

- 9

- 0

Hi all,

I am looking for the correct calculation of the torque (or linear force) that is needed on a syringe plunger to overcome a backpressure at the nozzle of 20,000 psi.

I have to decide which syringe pump I will be using for my application, but their is a lot of choice and mainly I need enough linear force to overcome 20,000 psi back pressure.

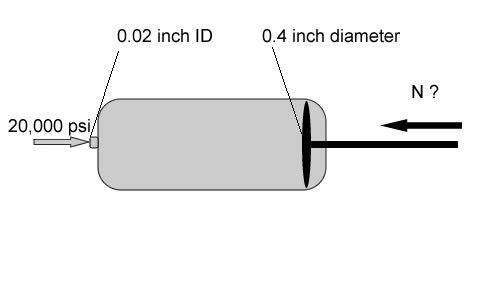

The plunger has a diameter of 0.4 inch , the nozzle has an internal diameter of 0.02 inch. Let us say that the syrine is filled with water and the backpressure is also coming from water that is restricted by a back pressure regulator of 20,000 psi (not the real case, but to keep it simple).

In attachment I have put a drawing of my question.

I hope someone can help. Apparently this is not such an easy question, as all syringe pump manufacturers give me an ambiguous answer.

I am looking for the correct calculation of the torque (or linear force) that is needed on a syringe plunger to overcome a backpressure at the nozzle of 20,000 psi.

I have to decide which syringe pump I will be using for my application, but their is a lot of choice and mainly I need enough linear force to overcome 20,000 psi back pressure.

The plunger has a diameter of 0.4 inch , the nozzle has an internal diameter of 0.02 inch. Let us say that the syrine is filled with water and the backpressure is also coming from water that is restricted by a back pressure regulator of 20,000 psi (not the real case, but to keep it simple).

In attachment I have put a drawing of my question.

I hope someone can help. Apparently this is not such an easy question, as all syringe pump manufacturers give me an ambiguous answer.