Discussion Overview

The discussion revolves around the design of model rockets, specifically addressing why the motor tube does not include a retention ring to prevent the motor from exiting through the nose cone. Participants explore various aspects of model rocket construction, including the role of friction, retaining rings, and the implications of motor design on rocket stability.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

Main Points Raised

- One participant questions the absence of a retention ring in the motor tube, suggesting that friction alone cannot hold the motor in place.

- Another participant notes that their past experience with model rockets included retaining rings glued to the interior to prevent engine motion.

- It is mentioned that for rockets with a body diameter matching the motor, a simple ring suffices, but without sufficient friction, motors could fall out before launch.

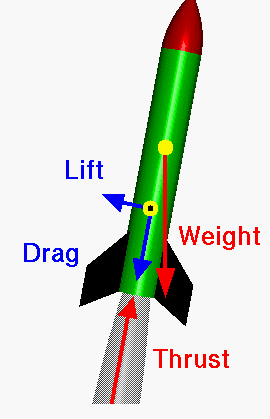

- A participant speculates about the mass distribution in the rocket, questioning whether the engine block accounts for most of the total mass and how friction and rings transmit force to the rest of the rocket.

- Another contributor recalls that in their experience, the engine rings and body were made of lightweight materials, suggesting that the motor's weight is significant compared to other components.

- Discussion includes the design differences in larger model rockets, where motors may lack a forward stop due to the need for varying motor lengths, which are instead designed with a rear stop.

- One participant reflects on their past experiences with metal clips used in some models, questioning their current prevalence and applicability across different rocket designs.

- Another participant clarifies that the use of clips or rings depends on the diameter of the rocket, with different mounting systems employed for varying sizes.

Areas of Agreement / Disagreement

Participants express differing views on the necessity and design of retention mechanisms in model rockets, with some recalling specific practices from their experiences while others present alternative perspectives. The discussion remains unresolved regarding the best practices for motor retention in various rocket designs.

Contextual Notes

Participants reference personal experiences and historical practices in model rocket construction, which may not reflect current standards or designs. There is also mention of varying designs based on rocket size and motor length, indicating a lack of consensus on a single approach.