- #1

SaiQmon

- 3

- 0

Hi there,

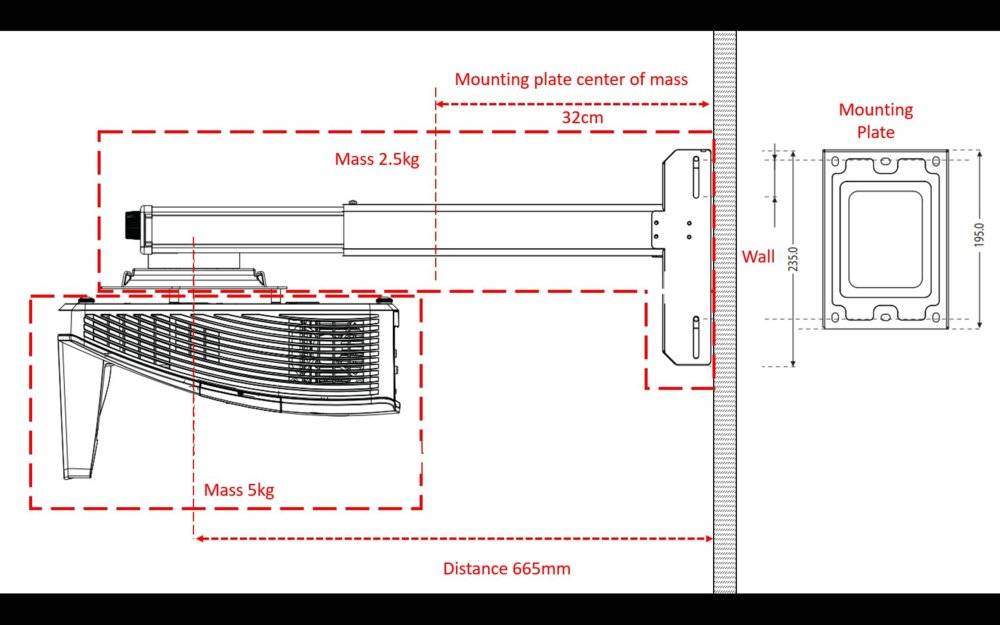

I'm going to install same kind of short throw projector in multiple locations, with different wall materials. Projector has integrated wall mount arm (see picture).

- How to calculate total torque affecting mounting plate top row screws?

Some locations have plasterboard walls. Board itself will handle this load, but mounting screws can take only 0.15kN / each for plasterboard.

I'm going to install same kind of short throw projector in multiple locations, with different wall materials. Projector has integrated wall mount arm (see picture).

- How to calculate total torque affecting mounting plate top row screws?

Some locations have plasterboard walls. Board itself will handle this load, but mounting screws can take only 0.15kN / each for plasterboard.

##\qquad## !

##\qquad## !