Cheesycheese213

- 55

- 8

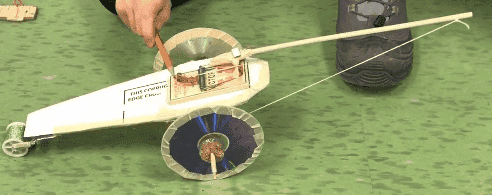

Hello, so for school I'm building a mousetrap with my group for a project, but our car isn't moving. We filmed it snapping, and it doesn't seem like it is because of friction, since the axle spins pretty well. We thought that it was because the thing that holds the axle bends, but after fixing it, it still doesn't roll. We tested it without the mousetrap being set, but when pushing the dowel towards where the mousetrap would snap, it did not move the wheels or the axle. We noticed that when pushing it back, it did roll. I have a picture of it set, but we're not quite sure why it still doesn't work. Could anyone help? Thanks!