- #1

ricardo kuhn

- 27

- 0

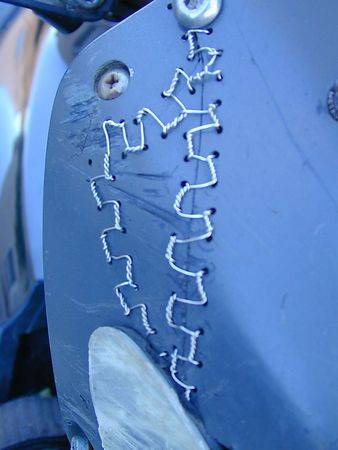

"PLastic Surgery" as a form of expression

I ride Motorcycles a lot,,, I also crash motorcycle A lot... ussually my body do just fine but sadlly the bikes end up suffering a little more, so over the years I develope a varaity of ways to keep them running without replacing parts every time something breaks, one of my favorites is a way to Joing two or more plastic pieces on damage surfaces in a way that shows the "Battle Scares" in a proud way, as oppose to be ashame of the fact and try to hide them some how, plus is really strong flexible and for sure RE-CrAsHaBle.

yes,,I know how to use a plastic welder, but some of this plastics are Thermoset resins, so the welding will not work and many time I'm also uniting disimilar materials that will make welding very difult if not imposible, i also work making composites Airplanes before and I'm awere of the Exo and polisterm resin and all the wonderful carbon, spectra, kevlar clothes available, but i don't like to use them since they stick and they make a big mess...

anyway one day I crash one of my race bikes and I broke the "Windscreen" among a few other things

so i did some "Face lifting"

some how i preffer to fix things and BE PrOuD of my adventures

i also done the same for others wunded bikes.

many war veterans mension that they see similar sistems use in time of war to fix helicopter bubbles and airplane cockpits, I believe this sistem and also much better since does not relay on the tension at the end of the wire and each strand forms a "close loppe" on his own.

I ride Motorcycles a lot,,, I also crash motorcycle A lot... ussually my body do just fine but sadlly the bikes end up suffering a little more, so over the years I develope a varaity of ways to keep them running without replacing parts every time something breaks, one of my favorites is a way to Joing two or more plastic pieces on damage surfaces in a way that shows the "Battle Scares" in a proud way, as oppose to be ashame of the fact and try to hide them some how, plus is really strong flexible and for sure RE-CrAsHaBle.

yes,,I know how to use a plastic welder, but some of this plastics are Thermoset resins, so the welding will not work and many time I'm also uniting disimilar materials that will make welding very difult if not imposible, i also work making composites Airplanes before and I'm awere of the Exo and polisterm resin and all the wonderful carbon, spectra, kevlar clothes available, but i don't like to use them since they stick and they make a big mess...

anyway one day I crash one of my race bikes and I broke the "Windscreen" among a few other things

so i did some "Face lifting"

some how i preffer to fix things and BE PrOuD of my adventures

i also done the same for others wunded bikes.

many war veterans mension that they see similar sistems use in time of war to fix helicopter bubbles and airplane cockpits, I believe this sistem and also much better since does not relay on the tension at the end of the wire and each strand forms a "close loppe" on his own.