- #1

longz

- 11

- 0

Hi every body,

I need help to calculate the pressure drop to double wall pipe with information as below, i understand need calculate pressure loss to the straight pipe, elbows and supports but I don't know exactly how.

- Fluid : air

- Double wall pipe (stainless steel) with outer pipe OD89mm, wall thickness 3mm, inner pipe OD61mm, wall thickness 2mm. the air will blow into the void between inner and outer pipe

- Pipe distance : 7m.

- Number of 90 degree elbow : 7 pcs

- Number of plastic support to inner pipe : 9 pcs

- Air flow capacity 28 m3/h equivalent 7.8 L/s.

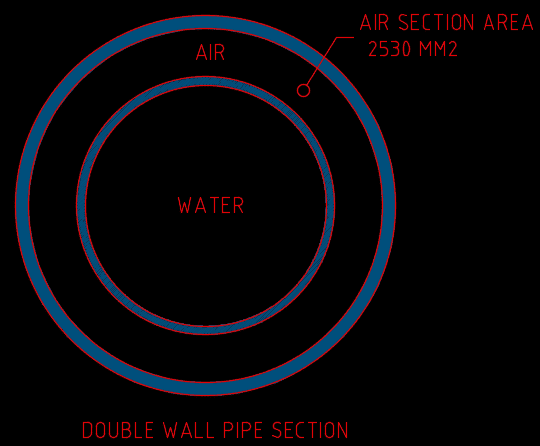

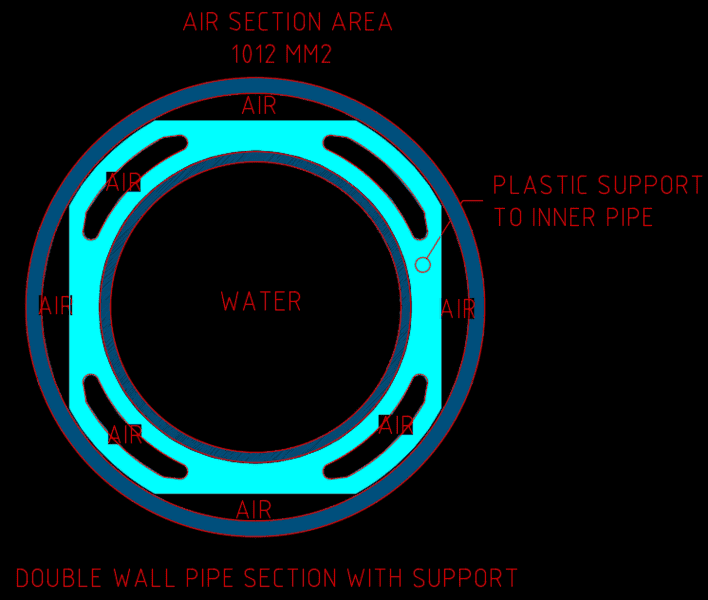

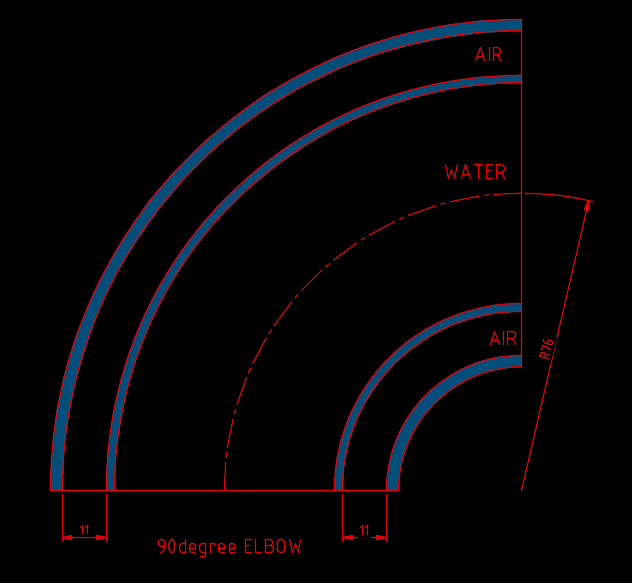

Some drawing for clear view:

1. Double wall pipe section

2. Double wall pipe section with support, the support is obstruction to the air flow similar to orifice.

3. Elbow

Thank every body.

I need help to calculate the pressure drop to double wall pipe with information as below, i understand need calculate pressure loss to the straight pipe, elbows and supports but I don't know exactly how.

- Fluid : air

- Double wall pipe (stainless steel) with outer pipe OD89mm, wall thickness 3mm, inner pipe OD61mm, wall thickness 2mm. the air will blow into the void between inner and outer pipe

- Pipe distance : 7m.

- Number of 90 degree elbow : 7 pcs

- Number of plastic support to inner pipe : 9 pcs

- Air flow capacity 28 m3/h equivalent 7.8 L/s.

Some drawing for clear view:

1. Double wall pipe section

2. Double wall pipe section with support, the support is obstruction to the air flow similar to orifice.

3. Elbow

Thank every body.