SUMMARY

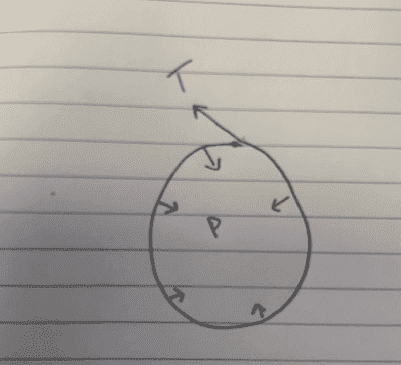

The relationship between the pulling force (F) applied to a non-elastic belt and the pressure exerted on an elastic object is defined by the equation F = 2θrp - 2Tsin(θ), where p represents the force per unit length and r is the radius of the elastic object. For equilibrium conditions, the tension (T) in the belt is directly proportional to the product of the radius (r) and the pressure (p), expressed as T = rp. This establishes a clear mathematical relationship between the applied force, the belt tension, and the resultant pressure on the elastic object.

PREREQUISITES

- Understanding of basic mechanics and forces

- Familiarity with tension and pressure concepts

- Knowledge of angular measurements in radians

- Basic algebra for manipulating equations

NEXT STEPS

- Study the principles of tension in non-elastic materials

- Explore the mechanics of elastic deformation in materials

- Learn about the applications of force and pressure in engineering contexts

- Investigate the mathematical modeling of forces in circular systems

USEFUL FOR

Mechanical engineers, physics students, and anyone interested in the mechanics of materials and the relationship between force, tension, and pressure in elastic systems.