- #1

kalkyl

- 3

- 0

Summary:: What does I need to consider in order to get the right spring?

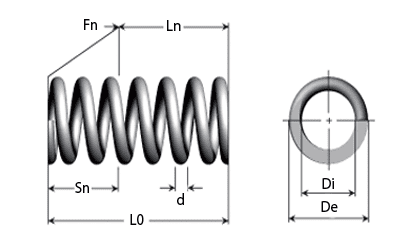

Hello. I need a compression spring that require 10 lbs of force in order to be compressed 1cm. The springs outer diameter (De) has to be 1cm. The spring will be made out of piano wire. Which values of specification does the spring need to have?

Hello. I need a compression spring that require 10 lbs of force in order to be compressed 1cm. The springs outer diameter (De) has to be 1cm. The spring will be made out of piano wire. Which values of specification does the spring need to have?