Discussion Overview

The discussion revolves around material selection for a component in a clamp that involves stainless steel parts and concerns about friction and galling. Participants explore alternatives to stainless steel for a part that must withstand pressure without lubrication, considering various materials and their properties in relation to corrosion and wear.

Discussion Character

- Technical explanation

- Debate/contested

- Exploratory

Main Points Raised

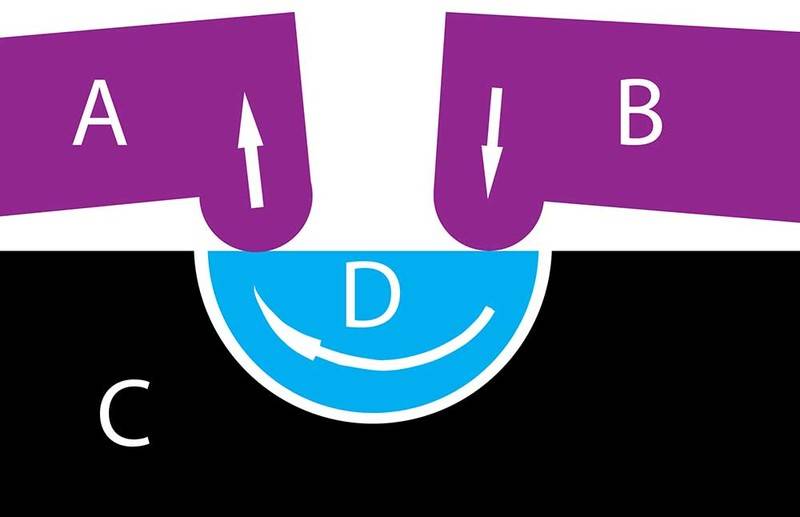

- One participant expresses concern about galling with stainless steel and suggests considering plastics like Tufnol or ceramics for part D.

- Another participant mentions that brass does not gall against stainless steel and recommends Nylatron as a suitable plastic for gears.

- A suggestion is made to use a strip of PTFE or Nylon between D and C, with D potentially being made of brass or bronze for added strength.

- It is proposed that brass or bronze would be effective where A and B contact D, and UHMW tape is recommended to reduce friction between C and D.

- A participant expresses hesitation about using tape due to concerns about the force applied and the need for durability in the clamp's function.

- Questions are raised about the corrosive fluid involved, with a note that bronze has fewer corrosion issues than brass, and that stainless steel's properties depend on the oxygen environment.

- Concerns are discussed regarding the efficiency of lubrication due to the inability to seal the C to D surface, and the potential for grit to act as an abrasive if D is plastic.

- Technical considerations are made about the force distribution and contact areas between A, B, and D, emphasizing the importance of alignment and contact geometry to minimize wear.

- A participant acknowledges the relevance of the points made about surface contact and clarifies the environmental conditions for the clamp's use.

Areas of Agreement / Disagreement

Participants present multiple competing views on material choices and their properties, particularly regarding the suitability of brass, bronze, and various plastics. The discussion remains unresolved with no consensus on the best approach.

Contextual Notes

Participants express uncertainty about the specific corrosive environment and the implications for material selection. There are also unresolved considerations regarding the mechanical design and contact pressures that may affect performance.