Jeremy Sawatzky

- 33

- 13

- TL;DR

- I need to know if my 440C track roller will put an indentation in my SS304 surface when subjected to 2000lbs of force.

I have a machine I am designing that has a carriage supported by Track rollers on a machined flatbar track.

The load that each individual roller will experience could reach 2000lbs. worst case scenario.

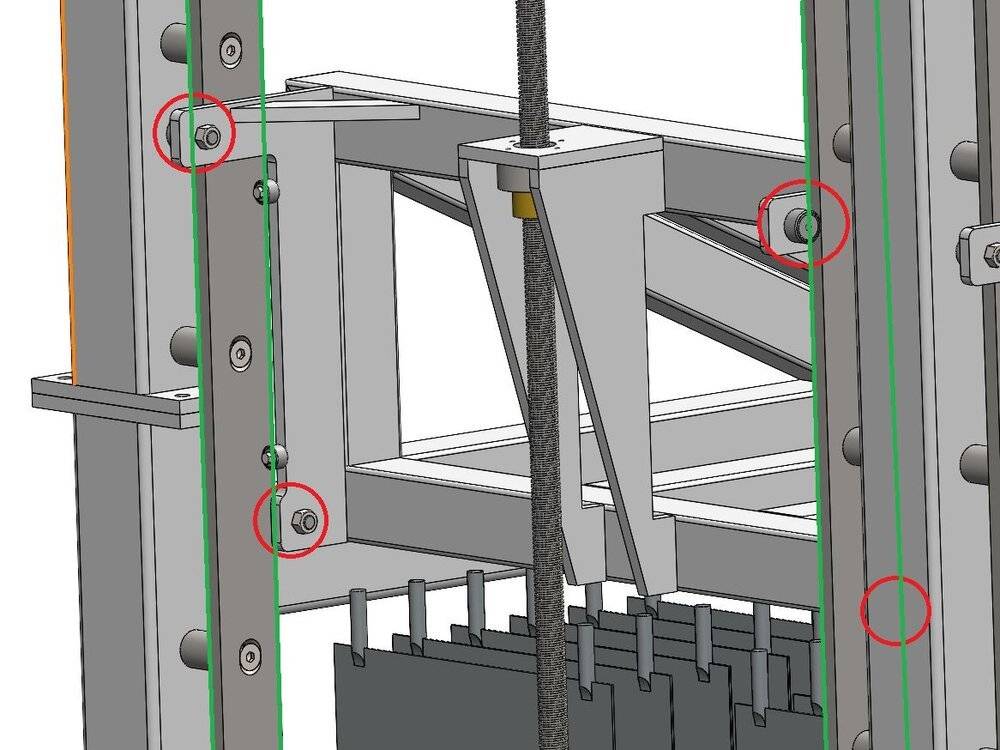

The track surface is machined 304L - 1" wide as you can see in the green in the attached image.

The rollers are made from 440C and cover the full width of the 1" wide track. The roller diameter is 1.75" - the rollers are circled in red.

What calculation can I do that will show how much of an indentation that the track roller will push into the track surface? I am trying to plan if I need to attach a harder metal strip on top of the track to handle the load. - or if I am being overly cautious and I can reduce the width of the track for lower material costs.

Thank you!

The load that each individual roller will experience could reach 2000lbs. worst case scenario.

The track surface is machined 304L - 1" wide as you can see in the green in the attached image.

The rollers are made from 440C and cover the full width of the 1" wide track. The roller diameter is 1.75" - the rollers are circled in red.

What calculation can I do that will show how much of an indentation that the track roller will push into the track surface? I am trying to plan if I need to attach a harder metal strip on top of the track to handle the load. - or if I am being overly cautious and I can reduce the width of the track for lower material costs.

Thank you!