- #1

diy-er

- 14

- 2

- TL;DR Summary

- vertical square steel tube construction load

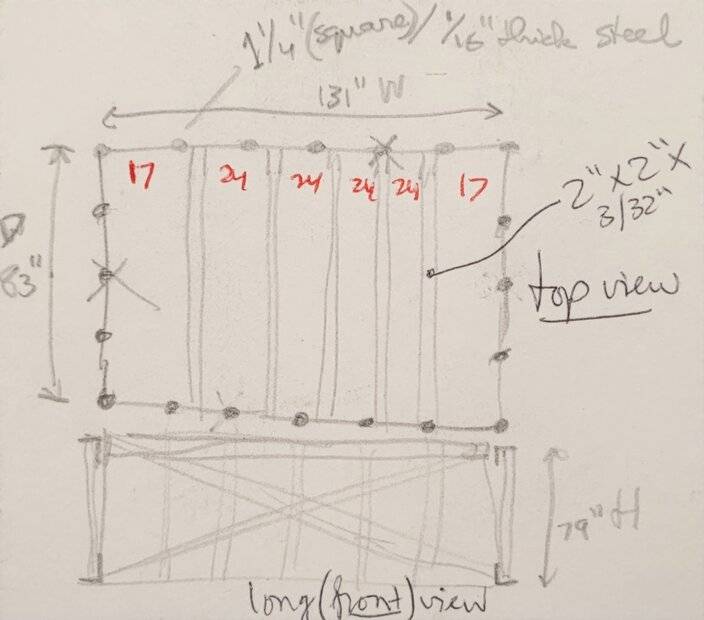

I have a VERTICAL standing square tube 1.25" x 1.25" x 1/16" thick.

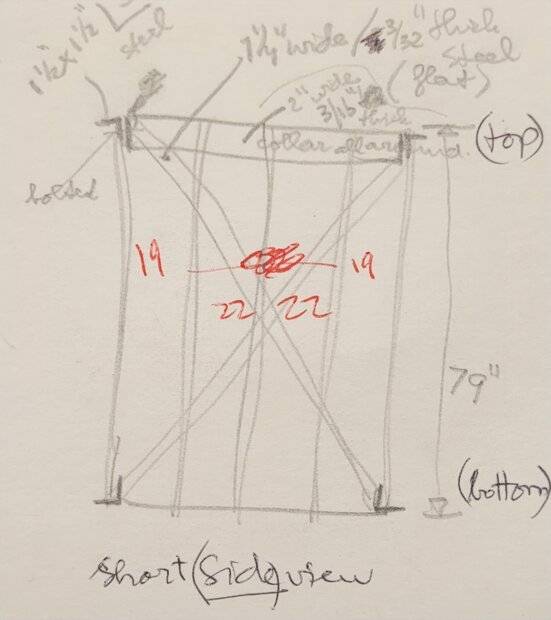

Length/Height = 79"

Material = steel

How do you determine its max load capacity for this tube when mounted vertically?

I plan to use 18 of these vertical posts, evenly spaced, creating an 83" x 131" rectangular structure.

They will be welded together on the top, as well as on the bottom, by 2" steel L-bars (3/16" thick), 4 pieces of 83" length, and 4 are 131" long.

Next I will weld a cross (on all 4 sides for structural integrity), made with steel flat bars of 1.25" x 3/32" thick.

Finally it will have the top connecting the long sides, with 5 horizontally mounted, evenly spaced 2" x 2" x 3/32" square steel tubes.

My question is what the load capacity is per post, per square foot, and/or for the entire stucture.

Thank you

Length/Height = 79"

Material = steel

How do you determine its max load capacity for this tube when mounted vertically?

I plan to use 18 of these vertical posts, evenly spaced, creating an 83" x 131" rectangular structure.

They will be welded together on the top, as well as on the bottom, by 2" steel L-bars (3/16" thick), 4 pieces of 83" length, and 4 are 131" long.

Next I will weld a cross (on all 4 sides for structural integrity), made with steel flat bars of 1.25" x 3/32" thick.

Finally it will have the top connecting the long sides, with 5 horizontally mounted, evenly spaced 2" x 2" x 3/32" square steel tubes.

My question is what the load capacity is per post, per square foot, and/or for the entire stucture.

Thank you